Project Profile: Barstow's Longview Farm

Highlights

- Third-party owned and developed system

- Food waste is mixed with dairy manure to boost project profitability through tip fees and increased biogas production

- Successful example of digester technology and nutrient management solutions scaled down for a medium-sized farm

View a printer-friendly version of this profile

Pursuant to 5 CFR § 2635.702(c)(2), names are displayed here as the result of recognition for achievement given under an agency program of recognition for accomplishment in support of the agency’s mission. Any reference to a specific company or commercial product or service by trade name, trademark, manufacturer, company, or otherwise does not constitute or imply the endorsement or recommendation of EPA.

"Our motto is 'Looking Forward since 1806' - We strive to consider the Earth and our community and to grow a more efficient and sustainable business."

– Steven Barstow II, Barstow’s Longview Farm

Founded in the early 1800s, Barstow’s Longview Farm is a family farm managed and owned by sixth- and seventh-generation members of the Barstow family. The 450-acre dairy farm produces 19,000 pounds of milk daily and operates Barstow’s Dairy Store and Bakery. The farm offers farm tours to the local community and visitors. Barstow’s Longview Farm is a member of the Cabot Creamery/Agri-Mark Cooperative, which has a membership of more than 1,000 family dairy farms in New York and New England. The Barstow family’s commitment to pursue sustainable farming practices led them to establish a partnership with Vanguard Renewables to build one of the first farm-powered anaerobic digesters in New England.

Creating Renewable Energy and Fertilizer from Manure and Food Waste

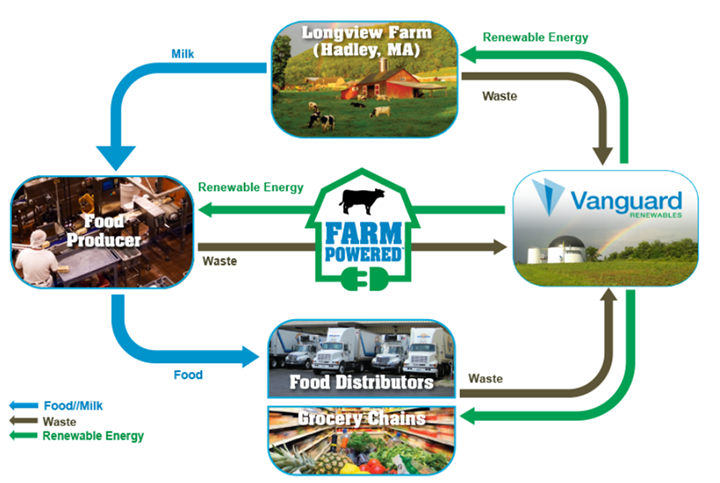

The partnership between Barstow’s Longview Farm, Vanguard Renewables, and Cabot Creamery/Agri-Mark Co-Operative made this farm-powered anaerobic digester project possible. The anaerobic digester, installed in 2013, was expanded in 2016 and is one of the largest anaerobic digestion systems in New England.

The anaerobic digester at the farm converts manure and food waste into electricity, heat, and fertilizer. Milk produced at the farm is supplied to the nearby Cabot Creamery/Agri-Mark Cooperative plant and the resulting organic by-products from milk and butter production are sent to the anaerobic digester at Barstow’s Longview Farm. All of the power needed to operate the Agri-Mark Cooperative plant is provided by the Barstow’s farm-powered anaerobic digester. The digested manure and food waste is used at the farm as a chemical-free fertilizer and has helped to increase hay and corn yields. The digester helps Barstow become a sustainable, closed-loop system.

Benefits

Barstow’s Longview Farm anaerobic digester advances sustainability in the following ways:

- Provides Cabot Creamery/Agri-Mark Cooperative with renewable energy used to produce dairy products

- Reduces pathogens in digested manure, protecting human health

- Farm tours provide the opportunity for people to learn about farm-powered renewable energy, as well as where their food comes from and how it can be sustainably produced

- Protects local water resources by reducing nutrient run-off and destroying pathogens

- Reduces the use of petrochemical fertilizers

- Diverts food waste and dairy processing waste from landfills

- Reduces greenhouse gas emissions, which can mitigate some of the impacts of climate change on human health and the environment

- Reduces operating costs at the farm by producing energy and generating heat and hot water

- Farm realizes an added $100 to $200 in revenue per cow in annual revenue from the digester

- Manure treatment and nutrient application comply with manure management regulations, saving additional investment

About the Digester

The 600,000-gallon complete mix digester, developed and operated by Vanguard Renewables, currently receives approximately 9,000 tons of manure a year from the farm’s 250 cows and 22,000 tons of food waste delivered from local supermarkets and food processing facilities, including those associated with the Cabot Creamery Cooperative. Baseline testing is conducted on all incoming waste sources to determine the energy content of feedstocks. The waste is separated based on the waste’s energy content, and then stored in three receiving tanks adjacent to the digester. To maximize biogas generation, a specific ratio of waste to manure is fed into the anaerobic digester.

"One Barstow cow produces enough electricity to power an average Massachusetts home."

– Steven Barstow II, Barstow's Longview Farm

The anaerobic digestion process produces approximately 30,000 tons of liquid effluent that is used as fertilizer on the farm. The energy produced by the farm-powered anaerobic digester system powers the farm and provides heat and hot water to the farm and family homes. Power is also sold to the Eversource grid as renewable energy. Energy credits generated by the project are sold to the nearby Cabot Creamery/Agri-Mark Cooperative plant. The project produces more than 6,000 megawatt hours of energy per year, which is equivalent to the energy needs of 1,000 homes.

System Design Properties

| Property | Value |

|---|---|

| Feedstock processed | Manure, Food Waste, Food Processing Waste |

| Digester type | Complete Mix |

| Developer | Vanguard Renewables |

| Herd Size | 250 Cows |

| Generating Capacity | 800 kW |

| Through put | 300 gallons/hour |

| Biogas generation | 23,900,000 scf/year |

| Biogas uses | Electricity, Heat, Hot Water |

Recognition

Barstow’s Longview Farm has received awards and recognition for its farm-powered anaerobic digestion project and focus on sustainable farming practices:

- “Agricultural Project of the Year” award from the American Biogas Council in 2016.

-

- “2016 Massachusetts Outstanding Dairy Farm” award under the New England Green Pastures program, which recognizes farms for their production records; herd, pasture, and crop management; environmental practices; contributions to agriculture and the local community; and overall excellence in dairying.

Want to learn more?

For more information about Barstow’s Longview Farm, visit their website.

Visit Vanguard Renewable’s website for information about its partnership with Barstow‘s Longview Farm and their anaerobic digester program.

Learn more about the Cabot Creamery/Agri-Mark Dairy Farmer Co-operative.