Management Information Systems Improve Operational Efficiencies and Air Quality At Ports

One this page:

- Overview

- Efficiency Strategies

- Key Advantages of Port Management Information Systems

- Strategy Implementation Considerations

- Cost and Savings Components

Overview

See the fact sheet on Port Operational Strategies: Port Management Information Systems (PDF) (March 2021, EPA-420-F-21-007)

Ports around the world have implemented variations of PMIS. Many major U.S. ports have implemented PMIS to varying extents including the Port of Virginia, Port Authority of New York and New Jersey, Port of Oakland, and Port of Los Angeles. Ports of any size can benefit from a well-designed PMIS, with large and complex container operations benefiting the most.

Efficiency Strategies

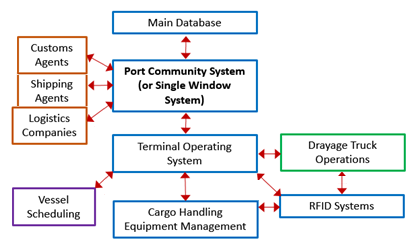

PMIS may focus on a subset of port functions or encompass all freight movement activities, integrating multiple efficiency improvement strategies. Port functions that may be managed by PMIS include:

- Advanced vessel scheduling: Also known as virtual vessel arrival, this strategy informs vessel operators to anticipate delays at destination ports, reducing or eliminating vessel wait times and associated anchorage emissions.

- Drayage operations: Drayage efficiency can be improved through various gate management strategies [link to GMS page], including truck appointment systems and extended operation hours, both of which shift truck arrivals away from peak periods and reduce average wait times at the terminal gates.

-

Figure 2: Automatic Guided Vehicle Transporting 20-Foot Containers - Automated gate systems: These systems identify vehicles and containers to facilitate access, loading, and unloading of cargo entering the terminal gate, reducing truck wait times and idle emissions.

- Terminal operating systems: These systems operate at the individual terminal level, providing centralized, integrated control of all terminal functions including scheduling and management of vessels, drayage trucks, CHE, and containers.

- Port community/single window systems: These systems track drayage trucks, containers, and ships, allowing port operators to see all information in a “single window” and providing stakeholders with access to selected operational data.

Key Advantages of Port Management Information Systems

- PMIS can reduce the time and fuel needed for ships to approach and dock, decrease the number of container movements within the terminal yard, improve drayage truck turn times and reduce traffic congestion.

- By increasing port operational efficiency and reducing the movement and idling of vessels, vehicles, and equipment, PMIS can significantly reduce port-related emissions and noise which can improve the health of port workers and nearby communities (see example emission reduction calculations for drayage trucks and cargo handling equipment (PDF) ( March 2021, EPA-420-F-21-007)

- PMIS can reduce demurrage, detention, and other costs associated with delays for both shippers and drayage carriers.

- By reducing total cargo moves, PMIS can improve port safety.

- PMIS can reduce port administrative requirements and decrease the incidence of misplaced cargo.

Strategy Implementation Considerations

- PMIS typically focus on container operations and may offer fewer benefits for bulk and other types of cargo.

- The data streams managed by PMIS often include confidential business information and data security must be ensured.

- PMIS offers the greatest potential efficiency improvements if the full range of operational functions are implemented together, as opposed to piecemeal upgrades, so the system can coordinate all aspects of container movements.

Cost and Savings Components

- Costs include initial labor for installation, system integration, and software development, as well as operational labor to manage and maintain the PMIS.

- Upfront software costs include system management and database software, commercial scheduling software, and communication system enhancement applications.

- Equipment costs may include scanners, tags, cameras, and gate/terminal receivers, and potential retooling or replacing CHE equipment to allow for automation.

-

Cost savings may result from reduced fuel consumption, labor, demurrage fees, and fines for truck idling.