EPA SBIR Supports Technology to Improve Recycling

The U.S. Environmental Protection Agency (EPA) is working to increase the circular economy, which keeps materials, products and services in use as long as possible, partly by recapturing items that might be considered waste and using them to manufacture new materials and products. Material recovery is important to slowing climate change because it reduces the need to extract and process natural resources, which contributes about half of all global greenhouse gas emissions. Improving the circular economy also increases social equity by reducing the need for landfills and manufacturing facilities, which often are located near disadvantaged communities.

Recycling is an important part of the circular economy—recycling items ensures their materials can be used again, meaning fewer new resources must be extracted from the environment. EPA’s Small Business Innovation Research (SBIR) program supports the development of new science and technology that protect public health from environmental threats, including those associated with climate change and resource overuse. The EPA SBIR program funded CleanRobotics Inc., Zabble, Inc., Verfilux Corp., Kamilo Inc., PKS Consulting Inc., and Rheaply Inc., to develop technologies to improve the recycling system.

Discarded items enter the waste stream and must be sorted and sent to an appropriate destination. CleanRobotics, Inc., created a smart recycling bin for public use, TrashBot, to sort waste into recycling, compost and landfill streams. TrashBot uses cloud storage and machine learning to determine what object has been dropped into its receptacle and how contaminated that object is. If the object is acceptable, TrashBot drops it into the appropriate bin. If a recyclable item is contaminated, TrashBot uses a built-in screen to educate people on why their item was sorted into the landfill bin. Discarding waste then becomes an educational experience, and each unit can be customized with artificial intelligence. Materials are especially likely to be contaminated in public areas where food is purchased and packed in single-use plastics, such as airports, hospitals and event venues. TrashBot takes on the consumer’s sorting responsibilities and improves the recycling stream with no additional effort from the consumer. It also provides an immediate moment for education and presenting the information in a new way helps consumers remember the information so they can recycle better next time. Trashbot's on-site sorting technology is best leveraged by facilities such as airports, hospitals, and stadiums, since they serve high volumes of people that dispose of waste without much thought. Case studies have shown significant improvement in diversion rates, custodial operations, procurement, compostable material alternatives, and overall public education of hundreds of thousands of visitors.

Zabble, Inc., is on a mission to help organizations achieve zero waste by delivering real-time actionable insights using artificial intelligence. Zabble Zero, an industry-first fully customizable web- and mobile-based platform for generators, consists of 2 products, (1) Invoice Analytics, that allows users to digitize hauling invoices and reports, automatically aggregate waste and diversion information and report billing inconsistencies and right-sizing options, and (2) Mobile Tagging, that allows users to digitize their bin infrastructure, conduct real-time visual audits with automatic bin fullness classification, detection of contaminants and instant notifications to stakeholders. Zabble is creating a zero waste blueprint for the educational and health industry by introducing a new paradigm for waste and workflow management. Zabble's clients include educational and health institutions such as Stanford, University of California San Francisco (UCSF) and UCSF Health. Zabble also works with several multi-family properties in the City of Atlanta through funding provided by The Recycling Partnership.

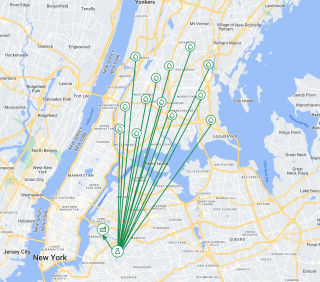

Companies and governments alike are turning to technology to enable traceability of recycled waste, including waste recycled for use as feedstock in renewable fuels such as biodiesel, renewable diesel, biogas and sustainable aviation fuel (SAF). Veriflux Corp developed a traceability platform capable of tracing biogenic wastes, fats and oils — such as tallow, brown grease and used cooking oil — across complex supply chains, providing stakeholders with the data needed to help comply with Federal and State regulations as well as lower carbon intensity (CI) scores. With EPA SBIR support, Veriflux was able to identify additional types of waste and feedstocks that can be traced with the system including food waste, plastics and other future potentially renewable materials. Veriflux has also launched a pilot with the NYC Department of Environmental Protection and Waste Management of New York, LLC to identify the source, and quantify the energy value of grease trap food waste. The pilot showcases the value of a platform like Veriflux, and the ability for technology and data to empower sustainability, circularity and traceability across waste, recycling and renewable energy supply chains.

Tracking can also reduce the amount of post-user material wasted when materials do not fully make their way through a recycling stream. Plastic waste lost to the environment, disposed of in landfills or burned can disproportionately affect communities already overburdened with environmental stress. Compared to new plastic products, little data is available on used and waste plastic. Stakeholders have indicated that improved data are essential for improving the recycling system. Kamilo, Inc., uses a unique digital identifier combined with geolocation intelligence to create circular traceability within the supply chain. With the company’s widely available mobile app, a user can enter and instantly upload data on a shipment of recycled plastics to an energy-efficient version of blockchain ledgers, providing a transparent, verifiable transaction log. Data that Kamilo collects on the movement of recycled plastic materials are more granular and better authenticated than previously possible, and its system rewards companies already contributing to the circular economy and encourages those who are considering using recycled plastics. Kamilo has a multi-year contract with a large durable goods manufacturer in the US providing verifiable circularity through tracking for multiple product lines.

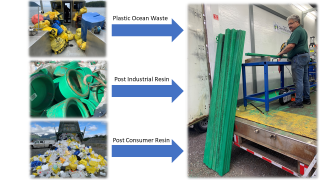

Some items do not end up in the waste stream but instead are discarded in the environment. PKS Consulting, Inc., an Alaska-based small technology firm, is working to turn discarded fishing gear and plastic found in the ocean into plastic lumber. PKS has developed a Mobile Plastic Ocean Waste Recycler that can be moved between remote communities where plastic ocean waste is collected. It has also analyzed the materials present in plastic ocean waste and identified a combination with properties similar to high-density polyethylene that can inform the company’s reformulation into plastic lumber. PKS plans to use its Mobile Plastic Ocean Waste Recycler to demonstrate a local and visible use for plastic ocean waste, which will encourage residents to participate in incentive programs for collecting and reducing ocean plastic. These pilot demonstrations, conducted in two coastal Alaska communities, will process at least 170 metric tons of plastic material—at least half of which should be plastic ocean waste and discarded fishing nets—while generating product sales.

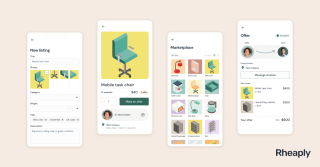

Construction and ongoing operation of the built environment extracts a large amount of resources on an ongoing basis. Embodied carbon—the emissions caused by all stages of constructing, maintaining and demolishing a building over its lifetime—is responsible for 11 percent of global greenhouse gas emissions. Managing materials more sustainably requires developing a more circular approach for these construction processes. Rheaply, Inc., has developed technology to scale workplace reuse of resources and materials. The company works primarily with commercial organizations that are aiming to improve material circularity of their building products and warehouse furniture. This built environment is the largest consumer of materials and energy worldwide, accounting for 40 percent of total energy and raw material use and 73 percent of total electricity consumption. Rheaply’s platform combines inventory management, resource exchange, and real-time reporting of embodied carbon and cost savings through reuse. Organizations can request and exchange surplus and reclaimed building materials internally or within permissible external network partners, allowing them to complete their projects more sustainably with less raw materials with the ability to tap into emerging end-markets to keep materials at their highest and best use. Rheaply has raised over $30 million in funding from investors to further scale their technology development efforts.

EPA’s SBIR program supports many other innovations that help protect human health and the environment. By coupling the latest technological advances with creative thinking about how people use and reuse resources, EPA and SBIR are improving the circular economy and building a more sustainable future.