EPA’s SBIR Circular Economy Projects Reduce Waste and Slow Climate Change

To help keep materials and products in circulation for as long as possible EPA is prioritizing a circular economy approach which focuses on more sustainable ways to design, use and manage materials—as well as change the relationship between production and growth. This is important to protect the environment and slow climate change.

Through its Small Business Innovation Research (SBIR) program, EPA supports the development of new science and technology that protects public health from environmental threats, such as the loss of resources and environmental damage caused by excess consumption. Sustainable materials management is a way to use and reuse materials more productively over their entire life cycles, preserving environmental resources and ensuring that our society has enough resources to meet current and future needs. Six small businesses funded by the EPA SBIR program to develop and optimize sustainable materials management technologies are highlighted below.

SBIR companies frequently look to the future, creating solutions for change and improvement of existing materials. The cement manufacturing sector reported emissions of over 66 million metric tons of carbon dioxide equivalent (MTCO2e) for 2020, an increase of 20% since 2011. The process of making cement has not changed since the Industrial Revolution, but KLAW Industries LLC developed a waste glass sorting system and high-performing cement alternative for supplementary cementitious material made from waste glass that currently is sent to landfills. The resulting material is stronger than traditional cement with a lower cost, and 97 percent lower carbon emissions. The mayor of the City of Binghamton in New York has specified KLAW's waste glass alternative for all curb and sidewalk upgrades. KLAW is scaling to meet the increased demand for high-performance, low-carbon concrete.

Verdant Structural Engineers (VSE) also is working to make building materials more sustainable. Most wall systems built in the United States emit carbon during production, so VSE created an alternative structural insulated panel made from straw. Because straw absorbs carbon from the atmosphere as it grows, preserving the straw from decomposition in these panels prevents the re-release of this carbon, resulting in negative carbon emissions. VSE’s straw panel concept was shown to easily meet the requirements and standard wall panel dimensions for use in the current building market. VSE is now continuing to develop its straw panels for single-family residential to mid-rise commercial buildings in most climate zones in the United States. Estimates suggest that 5 years of their production can store 74 million kilograms of carbon dioxide, the equivalent of more than 8 million gallons of gasoline. Verdant has incorporated the company that will manufacture their first panels, Verdant Building Products.

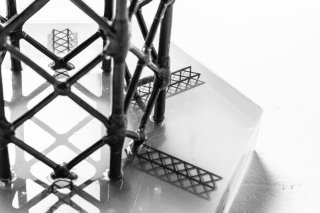

In addition to innovations in building construction, making infrastructure safer and more sustainable is crucial to protecting human and environmental health, particularly in earthquake prone areas.

IsoTruss Inc. is developing composite-reinforced concrete foundations to increase the resilience of telecommunication and other structures to extreme conditions. IsoTruss towers, which are more resistant to wind and corrosion than traditional towers, have already been adopted quickly by major tower owners in areas prone to hurricanes and typhoons. Composite materials are inherently resistant to corrosion, making the structures last up to five times longer than steel structures. This longevity and the smaller amount of material used in IsoTruss structures reduces the carbon emissions associated with these towers by 70 percent. IsoTruss has proved the feasibility and optimized the foundation design all without increasing cost or time. As a result of its overall efforts, IsoTruss continues to attract investments, including a Series A funding round.

Recycling is a challenge for many materials, often because the costs of recycling are higher than landfill disposal and the commercial value of recycled products is lower.

OLIN has partnered with the City of Philadelphia and local organizations to repurpose waste glass into soil for horticultural and green infrastructure projects, which will also serve the needs of the city in urban development of green spaces. OLIN developed both an engineered soil and an engineered process plan that cities can use to replace construction-grade sand with pulverized glass. These products also facilitate local processing, soil blending and installation, which improves the value for mixed-color, small-particle waste glass. Using recycled glass sand may reduce greenhouse emissions by 67 percent compared to standard sand, and the horticultural performance of OLIN’s soil is comparable to sand-based soil.

Major innovations are needed to create sustainable materials to support a circular economy and Ecotune Inc., a material science startup, is working to develop the next generation of 100% renewable materials. Ecotune develops and engineers advanced renewable materials that are high-performance, biodegradable, and scalable. Currently, most plastics are petroleum-based and difficult to recycle. Ecotune’s innovative technology platform enables the synthesis of strong, flexible, lightweight materials using cellulose, the most abundant organic polymer on Earth. The thin films developed can be composted both residentially and industrially, and they can be manufactured efficiently at scale using green chemistry principles.

A different strategy was piloted by USEFULL Inc., a tech-enabled circular economy solution designed to help universities and communities eliminate single-use food and beverage products. Stainless steel to-go cups and containers were provided to partners to help each reach their zero-waste goals. By using the USEFULL app, cups and containers were checked out and returned anywhere within the network by scanning the QR code on the bottom of the containers. Because the pilot community, Block Island, Rhode Island, did not ban single-use packaging, USEFULL focused their efforts on marketing, educating the public and prompting behavior change. USEFULL recently announced a successful pre-seed investment of $1.7 million from a venture capital firm. With this pre-seed investment, USEFULL has expanded their team and scaled the technology. USEFULL has implemented their solution in several communities and universities including: Mount Holyoke College, Carleton College, and two cities in California, Mill Valley and Fairfax.

In addition to these advances, EPA supports many other innovations through its SBIR program. Circular economy technologies are critical to ensuring the best use of limited resources in the future. EPA and its SBIR small businesses are working together to build safer and more effective materials that can help slow climate change and fulfill EPA’s mission to protect human health and the environment.