Supporting Innovative Water Reuse Technologies Through SBIR

As the climate changes and droughts become more common, water resource conservation and securing alternative water supplies are becoming increasingly important. Water reuse, or the practice of reclaiming water from a variety of sources, treating it, and reusing it for beneficial purposes, can help communities enhance the security, sustainability, and resilience of their water systems. In coordination with the National Water Reuse Action Plan (WRAP), EPA’s Small Business Innovation Research (SBIR) program supports water reuse innovations to drive progress on reuse and address technical, institutional, and financial barriers. Under WRAP Action 7.5, EPA’s SBIR Program supports innovations that can address gaps in current water reuse technologies.

EPA’s SBIR program funded five small businesses to develop new ways to treat and reuse water, which are highlighted below. The technologies range from household to commercial scale and aim to lower the cost of reuse through both high- and low-tech methods. The innovative approaches developed by these small businesses are providing new methods for reclaiming and treating water, reducing the demand on this natural resource and saving energy, money, and other resources.

On this page:

- Triangle Environmental Health Initiative

- LeapFrog Design

- Infinite Cooling

- Cambrian Innovation

- Pure Blue Tech

Triangle Environmental Health Initiative: Onsite Water Treatment and Resource Recovery

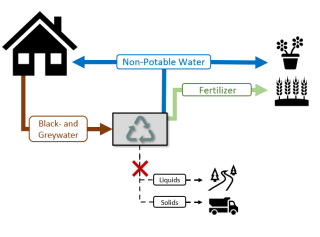

Triangle Environmental Health Initiative is developing onsite reuse solutions for multiple wastewater streams. Their Zero-Waste (ZeWa) system can be used to treat blackwater (wastewater from toilets and kitchen sinks) and graywater (wastewater from other home sources, such as bathroom sinks and laundry). The technology produces three kinds of valuable, high-quality outputs for reuse: clean water that can be reused for non-potable purposes (i.e., uses other than drinking), concentrated liquid fertilizer for agriculture, and solid organic material that can be used to amend local soils. The outputs created by the ZeWa system meet local and international standards for reuse, and the system can even treat combined black and graywater streams, so it is flexible enough to use in a variety of settings. Triangle Environmental is working with commercial and research partners to pilot seven systems (including stand-alone ZeWa subsystems). The company has won several awards and been featured in an article for Business North Carolina.

LeapFrog Design: Single-Home Water Treatment with Plants

Treating and reusing water at home can extend water supplies and reduce pollution caused by problems with wastewater infrastructure, helping families lower their impact on strained environmental resources and saving them money. Another company developing graywater treatment solutions is LeapFrog Design, which aims to provide innovative water treatment for single-family homes. LeapFrog’s technology incorporates the ecological processes found in wetlands into wastewater infrastructure to treat graywater at homes using a flexible, modular system. A planter box filled with plants cleans graywater from sinks, showers, and washing machines, which can then be returned to the household for non-potable uses in toilet flushing or irrigation. LeapFrog Design has received matching grants from Business Oregon and has been accepted into the U.S. Green Building Council Los Angeles’s Net Zero Accelerator program. The company also won its category at The Indus Entrepreneurs Oregon’s Pitch Oregon competition, which showcases talent and innovation among entrepreneurs and startups in the Pacific Northwest.

Infinite Cooling: High-Efficiency Cooling Towers

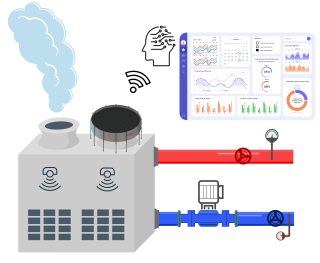

Cooling towers are used in various settings ranging from HVAC systems in commercial and residential buildings to large power plants. Infinite Cooling created multiple technologies for industries that use evaporative cooling towers to operate at high efficiency and minimize waste. Their TowerPulseä product uses a combination of remote sensing and artificial intelligence to provide real-time cooling tower monitoring, optimization, and decision support systems. This allows for less water and energy consumption in cooling towers and a significant increase in the efficiency of the equipment they are connected to (e.g., chiller or condenser). It also reduces the need for labor-intensive equipment inspections. Infinite Cooling’s WaterPanel™ innovation helps industrial facilities operate more reliably and efficiently by eliminating the steam plumes that are emitted from cooling towers and recovering their water content for reuse. It prevents outages due to cooling tower plume icing or reduced visibility, and it recycles a waste stream into valuable clean water. Infinite Cooling’s software and hardware technologies can be applied to a large market—including many industries in power generation, industrial process cooling, and chillers—and the company has projects underway with partners at ten sites across the country.

Cambrian Innovation: Turning Wastewater into Renewable Energy

Cambrian Innovation has developed multiple technologies that convert wastewater to renewable energy. While originally funded by the EPA SBIR program to develop a bio-electrochemical system to treat stillage—waste created during ethanol production--Cambrian has found commercial success with other bioelectrically enhanced wastewater treatment solutions that focus on resource recovery. Cambrian’s systems can generate electricity during wastewater treatment, reducing both the cost and the energy demands of industrial processes. Cambrian has over 30 customer sites in operation and its processes are used by some of the top names in food and beverage processing. Cambrian has also developed a business model in which it constructs, installs, owns, and operates systems and their client facilities pay on a per gallon basis. This “water energy purchase agreement” with Anchor Brewing was the largest commercial water reuse project in San Francisco history.

Pure Blue Tech: Integrated Ultrasound to Improve Membrane Filtration Efficiency

Many water and wastewater treatment and reuse systems use reverse osmosis to remove contaminants through membrane filtration. Over time, these membranes tend to accumulate organics, particles, bacteria and other residue on their surface, reducing the membrane’s performance through a process known as membrane fouling. Pure Blue Tech Inc. has developed a technology that uses ultrasound generated via thin, flexible, efficient transducers, embedded in the membrane filter. This technology effectively reduces the occurrence of membrane fouling by up to half compared with current technologies. As a result, this can lower the cost of reverse osmosis treatment through enhanced efficiency, reduced chemical cleaning, and reduced waste volume. The prototype technology has been successfully integrated in industrial-scale reverse osmosis systems. Reverse osmosis in wastewater treatment is key to many reuse applications, and Pure Blue Tech’s innovation can be incorporated into both new-build and retrofit water reuse markets. Integrated ultrasound may reduce or eliminate the need for expensive filtration pretreatment systems, which could save wastewater facilities millions of dollars. Pure Blue Tech has received funding from angel groups and other investors across North America and has pilot projects planned to advance this innovative membrane technology.

Through these projects and in coordination with EPA’s WRAP Action 7.5, EPA’s SBIR program is working to drive progress in technology innovation in the area of water reuse by supporting the development of innovative solutions that focus on resource recovery, energy efficiency and cost effectiveness to help meet the need for clean and safe water.