Lean & Water Toolkit: Chapter 2

Water Use and Water Waste at Industrial Facilities

- Definition of Water Waste

- Industrial Water Use

- Water End Uses: How Water Is Used at Facilities

- Measuring Facility Water Use: Metering and Submetering

- Costs Associated with Water Use

- To Consider

- Footnotes

- Toolkit Navigation

Definition of Water Waste

Water is one of the most critical resources in the world, and is necessary for all types of industry. Water is required in substantial quantities to create

goods from food products to silicon chips. In this toolkit, the term “water waste” refers to use of water beyond the point that optimizes value to the customer. This includes non-value-added water use throughout facility operations and support processes, and from the supply chain through production, product use, and waste disposal. Water waste can cause harm to health and well-being of people and ecosystems by diverting water from other needs and beneficial uses. Reducing water waste can help ensure that present and future generations have access to a sustainable water supply.

Improve your facility’s water efficiency by reducing water waste, not only by reducing water intake, but by finding creative ways to use water more efficiently. Water efficiency, as the term is used in this toolkit, refers to reductions in the amount of water used per unit of production. Water efficiency refers to the minimum amount of water needed to perform a task. (Note that water-efficiency improvements do not necessarily mean that a facility’s total water use is decreased, since increases in production may offset water efficiency gains.) Examples of water waste include:

- Loss of water through material failures, such as leaky hose nozzles

- Discarding water that could be reused, such as treated rinse water

- Wastewater discharges

- Water used by high-flow appliances instead of more efficient alternatives

- Use of water in excess of necessity, such as the use of too much water for facility or parts cleaning

Understanding the many places where water waste occurs is an important first step for identifying areas for improvement.

Industrial Water Use

The use of water by industries, both in the United States and throughout the world, represents a significant portion of total water use. U.S. industrial water use is estimated to be more than 18.2 billion gallons per day (from direct water withdrawals, not including water use from public water supply)1. While industrial water withdrawals account for just five percent of total water withdrawals in the United States, thermoelectric power water withdrawals account for 49 percent. Industrial and manufacturing businesses also use about 12 percent of the public water supply. Industrial water users include facilities involved in sectors such as chemicals, food and beverage, paper and associated products, steel, electronics and computers, metal finishing, petroleum refining, and transportation equipment. Overall, two of the most water consuming sectors of the economy are agriculture and thermoelectric power, although other industries may use a significant proportion of public water supplies in some areas.

The share of industrial water use can be much greater in certain geographic areas, and these areas can experience substantial supply pressures. Figure 3, below, shows a geographic distribution of water scarcity across the globe. Areas prone to water scarcity will likely experience continued competition for water resources, which can impact your relationship with the surrounding community. Be aware of your facility’s location relative to potential water scarcity, and consider water competition when siting new facilities or building relationships with new suppliers. In the United States, the National Integrated Drought Information System maintains a user-friendly web portal with current information, forecasts, maps, reports, and resources addressing drought conditions and water scarcity.

Industrial water use varies by sector, as different activities require different inputs of water. Box 6 lists eight industries that require substantial inputs of water.

Water is a very important resource to many industries, and as a result, there are many opportunities to reduce water use. In the case of the high-tech industry, which uses considerable quantities of water to manufacture semiconductors and other components, water is vital to industry operations. Cleaning and rinsing silicon chips can require billions of gallons of water per year; to produce a single chip can use up to 7,900 gallons2. Apparel also ranks high in the list of water-intensive industries, with cotton production and textile processing requiring substantial inputs of water. Among industrial manufacturers, the forest products sector is the third-largest consumer of water in the U.S., requiring high volumes of water for pulp and paper manufacturing. The electric power industry directly uses water extensively for cooling and emissions scrubbing; fossil fuel plants and nuclear power plants require hundreds of liters of water for every kilowatt-hour of electricity that they produce3. Table 1 shows typical water quantities required to produce one ton of several manufactured products.

There is much variation among industrial sectors in relative water use, and the need for water varies greatly across the stages of the product or service

value chain, from suppliers through production to product use. It is important to know where in the value chain your industry’s water use is heaviest, so that you can appropriately target improvement efforts. For example, the apparel industry uses high volumes of water in raw material production, whereas the biotech and pharmaceuticals industry uses most of its water resources in direct operations. Table 2 shows the relative intensity of water impact (ranging from zero to three squares) in different segments of the value chain for several industry sectors.

Water End Uses: How Water Is Used at Facilities

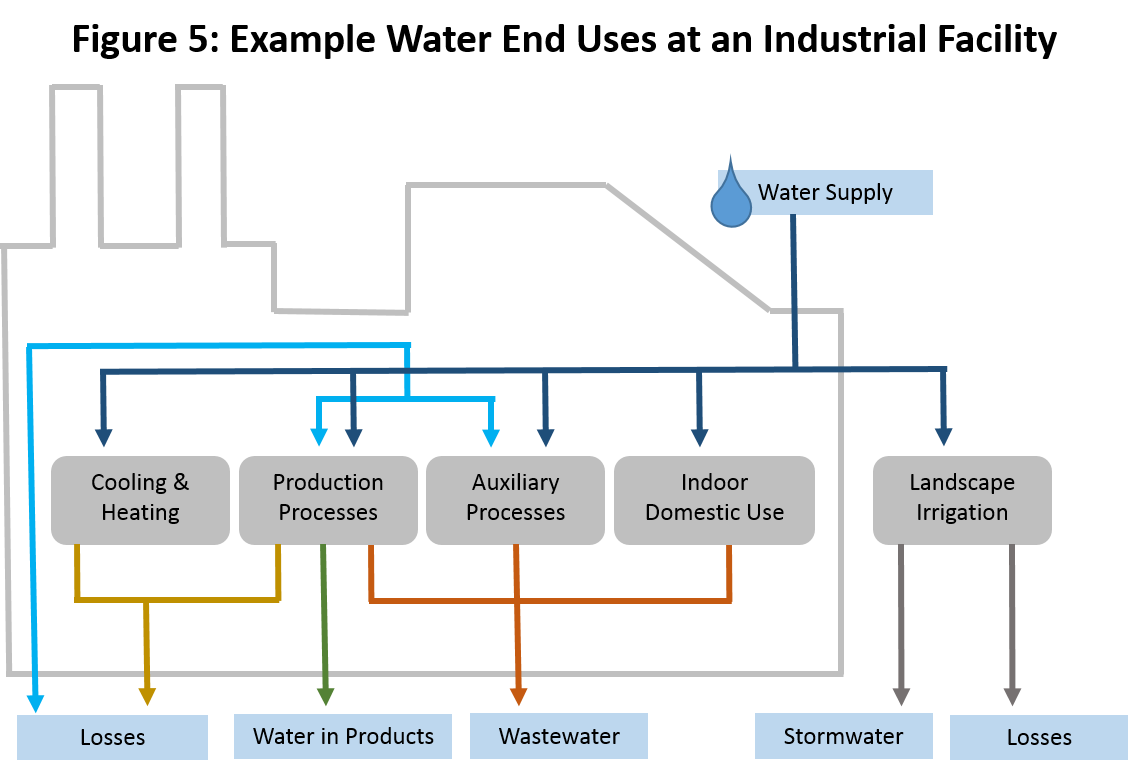

In order to reduce water waste in industry, it is important to understand the many ways that water is used within facilities. Understanding water end uses is critical to identifying water savings opportunities. While end uses of water vary by industry and by facility, there are categories of water use that are present at most industrial facilities. Water use in most industries can be classified into the following broad end uses:

- Production processing and in-product use

- Auxiliary processes (e.g., pollution control, labs, and cleaning)

- Cooling and heating (e.g., cooling towers and boilers)

- Indoor domestic use (e.g., restrooms, kitchens, and laundry)

- Landscape irrigation

These broad categories encompass many of the ways industrial facilities use water. Among U.S. industrial customers, cooling operations (including cooling towers and open cooling systems) comprise the single largest category of industrial water end use, with more than 50 percent of industrial and commercial water demand combined going toward cooling4.

The amount of water required for the various end uses differs by industry. Service and manufacturing facilities require the most water for washing and processing, while food and beverage facilities use most of their water intake in product preparation. Figure 4 shows examples of water end uses in the computer and electronics manufacturing industry and the food processing industry.

Major end uses of water often provide the greatest opportunities for water waste reduction and efficiency improvement. For example, in many food, beverage, and pharmaceutical companies, cleaning process equipment can account for as much as 50 to 70 percent of a facility’s total water use, and represents a substantial opportunity to save water5. Figure 5 illustrates how water flows through several different end uses at an industrial facility; note that this diagram does not incorporate all reuse options. Think of how a similar diagram would look that shows the water use at your facility.

Beyond these categories of water end use, specific industries have processes that demand significant amounts of water. For example, in the textile industry, a typical continuous fabric bleach range machine can consume 11,000 gallons of water per hour6.

Measuring Facility Water Use: Metering and Submetering

To gain a better understanding of water use patterns at your facility, it is almost always helpful to use water meters. Many Lean methods rely on the availability of timely and accurate information on key performance metrics. By measuring water use and flows at the facility and/or process level, it becomes much easier to identify water efficiency opportunities. As the saying goes, you can’t manage what you don’t measure. There are two types of water meters: Source meters measure the amount of water being supplied to the facility, while submeters measure usage for specific activities such as cooling towers, process use, or landscape water use.

Water meters can be either portable or fixed on specific equipment. Use portable water meters to measure water flows for processes or operations in your facility, as part of Lean efforts such as gemba walks, value stream mapping, and kaizen events (strategies discussed in Chapters 3-4). You can strap a hand-held acoustic water meter onto a pipe at a few places where you think there might be excessive water use. Compare the water data from the master meter to the water flowing through the pipes in the process to confirm where there are potential water savings opportunities. These data can help you develop a water balance (described in Chapter 3). See Appendix B for resources to help you determine rates of water use, including calculations and unit conversions.

Accurately measuring water use can help you identify areas for targeted reductions and track progress from water-efficiency upgrades. Submeters can also help identify leaks and indicate when equipment is malfunctioning. In some cases, it may also be useful to measure water pressure; a drop in pressure can indicate the presence of a leak. However, especially for smaller facilities, it will not necessarily make sense to use meters everywhere. Consider using meters when you have a need to closely track data; for example, before and after a process improvement event on a water-intensive process. You can use the data provided by the meters to compare water use and see how your efforts have improved your facility’s water efficiency. Larger facilities can also integrate meters into centralized building management systems, making it easy to electronically track water usage, generate reports, and trigger alerts when leaks or anomalies are found. For additional advice on when to use water meters, consult your local water utility or the resources in Appendix A.

Installing the correct meter and ensuring it functions properly are critical to accurate water measurement. There are many types and sizes of meters intended for different uses, so it is important to choose the correct one. Improper sizing or type of meter can cause problems. For example, an undersized water meter can cause excessive pressure loss, reduced flow, and noise. Oversized meters are not economical and do not accurately measure minimal flow rates7. It is also important to ensure that water meters are properly calibrated according to the manufacturer’s recommendation and that appropriate maintenance practices are followed on metering equipment. Most meters have internal mechanical parts and will begin to under-register the amount of water used as the meter gets older and the mechanical parts wear down. When abnormal water measurements are detected, check the metering equipment to ensure that the results are not due to metering equipment failures.

By metering water use at the facility and process levels, facility personnel can compile data to inform Lean improvement efforts. Here are some practical tips for using water meters as a part of Lean efforts:

- Use flow meters and water quality or cleanliness standards to establish standard work for water usage, flow, and pressure levels, taking into consideration “set points” recommended by equipment specifications and facility operating procedures. These baseline levels give important context of what accounts for “normal” operating parameters against which improvements and new water losses can be assessed.

- Use data that meters provide to determine the appropriate frequency for aggregating and reporting water measures (e.g., hourly, daily, or weekly) that best meets your facility’s needs.

- Show employees how to read and use water meters as part of Lean activities such as gemba walks, value stream mapping, and kaizen events, so that they can identify water savings opportunities.

- Post water use reduction goals and water usage information on the factory floor on Lean production control boards or in other accessible places to raise awareness of water use and efficiency among employees.

- Track data from water meters over time. Portfolio Manager, an online building performance benchmarking tool available from the ENERGY STAR program can help you track and benchmark water consumption data. For more information on the Portfolio Manager, see Appendix A.

Costs of Water Waste

As noted in Chapter 1, costs associated with water use include more than the direct costs you pay for water supply, but also the costs of water as it travels through processes and operations (see Figure 7). Box 7 provides examples of water costs, such as energy, pollution control, regulatory compliance, and raw material costs.

Estimating the many components of total water cost for a facility can begin with the cost of water purchased from utilities, but should also include the cost of steps required to process, use, and discharge the water. These costs can amount to a good deal more than what appears on a utility bill. When estimating water costs, it is important to consider these and other indirect costs throughout all functions of a facility. Be sure to use estimated future rates when assessing water costs, in order to project the level of savings that will be possible when improvements are made.

Full costs associated with water use often vastly outweigh the direct costs. The direct cost of purchasing water from a utility may not seem significant enough alone to merit the effort to reduce water use, but when the full cost of water is assessed, the financial savings can be substantial. Table 3 shows an example of the various costs of water in an industrial process. In this example, the estimated savings from implementing improvements using direct water and sewer costs alone is only 56 percent of the estimated savings using the full cost of water. The flexible cost savings of conserved water is estimated to be 40 percent of total treatment cost. Flexible treatment costs refer to expenses that vary according to the volume of water treated (e.g., energy used to pump and treat water, treatment chemicals); fixed costs (e.g., capital equipment used for treatment) do not typically vary as wastewater throughput changes.

Appendix B contains a Water Cost Calculator that provides a template for calculating common costs associated with water use at industrial facilities. It may also be useful to estimate the potential water and dollar savings that would result from implementing water efficiency measures at your facility; see Appendix C for some equations that you can use to guide these estimates.

In some water-stressed areas, industrial facilities may face the possibility of an even greater water-related cost—that of lost revenue from the need to curtail production in the event of water supply disruptions. Competition for water across residential, agricultural, industrial, and environmental needs during periods of water scarcity may lead local water managers to impose limits on industrial water use. Understanding the vulnerability to disruption of local water supplies can be an important consideration when assessing the true costs of water use when expanding or developing new facilities.

The next chapter discusses strategies for understanding how water is used at your facility and identifying opportunities to reduce water use and improve operations.

Footnotes

1 Kenny, Joan F. et. al. Estimated Use of Water in the United States in 2005. USGS. 2009. The USGS data does not include industrial water use drawn from municipal water systems, only direct withdrawals from surface and groundwater sources. Actual industrial water use is likely greater. For information on water use outside of the U.S., see AQUASTAT, Food and Agriculture Organization of the United Nations, “Water Withdrawal by Sector, Around 2003.” Note that FAO data includes thermoelectric cooling water withdrawals in its industrial water totals.

2 Uphadyay, Sanjay, “Microelectronics – Fostering Growth Opportunities in the Ultrapure Water Market.” Frost & Sullivan. August 19, 2011.

3 CERES and Pacific Institute, “Water Scarcity & Climate Change: Growing Risks for Businesses & Investors,” February 2009.

4 Vickers, Amy. Handbook of Water Use and Conservation. WaterPlow Press. 2001.

5 General Electric Company Water & Process Technologies, “Solutions for Sustainable Water Savings: A Guide to Water Efficiency,” 2007.

6 North Carolina Department of Environment and Natural Resources, Water Efficiency Manual for Commercial, Industrial and Institutional Facilities, May 2009.

7 Smith, Timothy A. Plumbing Systems and Design. Water-Meter Selection and Sizing. 2008.

Toolkit Navigation

- Contents & Acknowledgements

- Executive Summary

- Preface

- Chapter 1: Introduction

- Chapter 2: Water Use and Water Waste at Industrial Facilities

- Chapter 3: Finding Water Waste on the Factory Floor

- Chapter 4: Lean and Water Efficiency Improvement Strategies

- Chapter 5: Lean and Water Beyond the Factory Floor

- Chapter 6: Conclusion

- Appendix A: Water Efficiency Resources and Technical Assistance Providers

- Appendix B: Water Cost Calculator

- Appendix C: Water Unit Conversions and Calculations

- Appendix D: Water Efficiency Opportunity Checklist

- Appendix E: Glossary of Water Terms