The Leaking Underground Storage Tank Cleanup Process

Cleanup Process

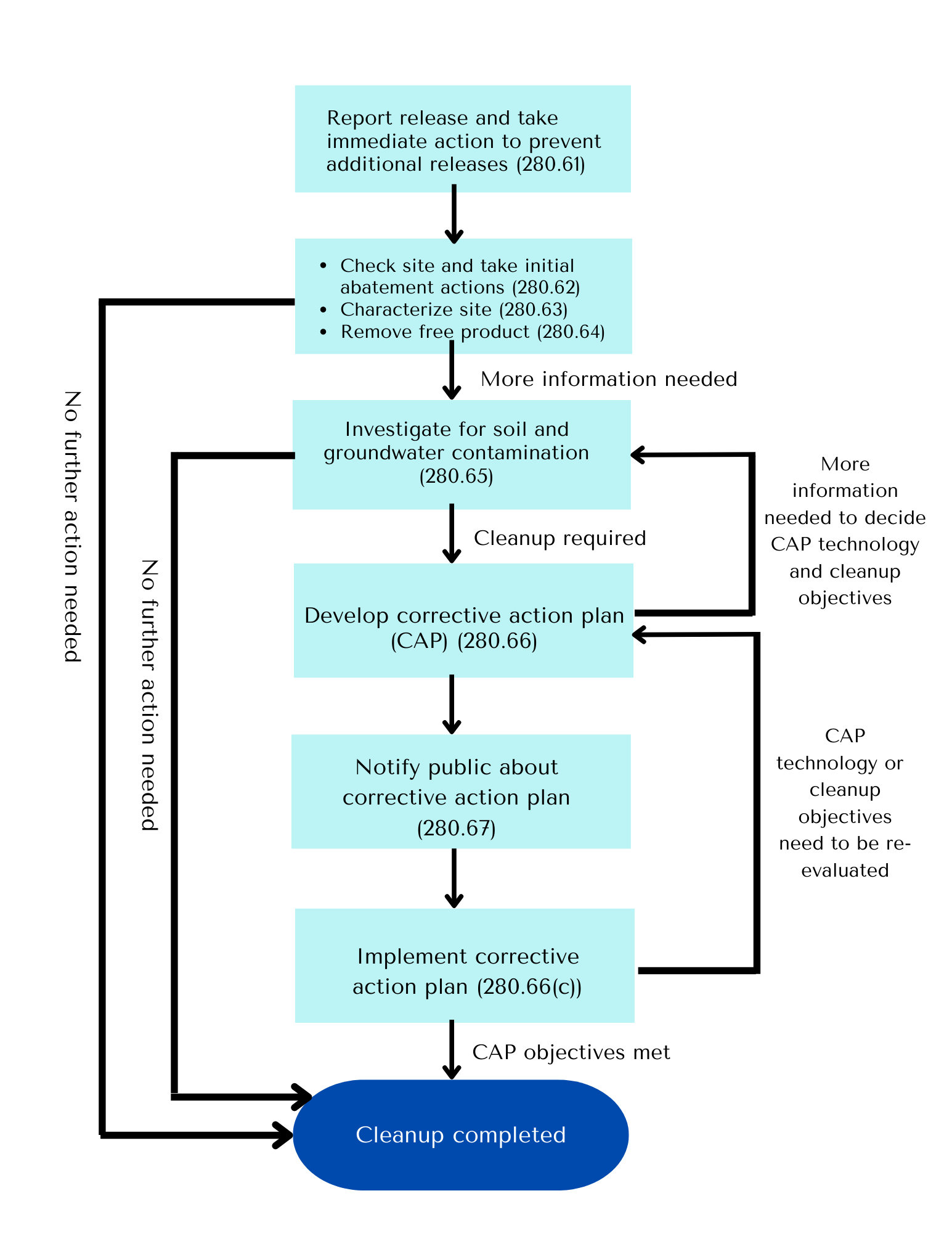

EPA describes the requirements for responding to petroleum or hazardous substances UST system releases, taking corrective actions, and completing remediation for those releases in 40 CFR 280 Subpart F. The flow chart below shows the steps in the cleanup process.

Note that the cleanup process varies greatly from site to site depending upon the circumstances of the release and the conditions of the site. Some sites may require a complex and long-term cleanup approach, while other sites may not require action beyond short-term cleanup of the initial release. EPA considers that developing a Conceptual Site Model and using risk-based decision making is critically important to the cleanup process.

Click the steps in the infographic below to learn more

Special Topics

- High resolution site characterization

- Conceptual site models

- Risk based decision making

- Greener cleanups

- Institutional and Engineering Controls

- Long-term stewardship and post closure reviews

- Petroleum contaminants to consider in LUST cleanups

- Petroleum vapor intrusion

Confirmed Release, or When do I report? (40 CFR Part 280 Subpart E)

A typical leaking underground storage tank scenario involves the release of a fuel product from an underground storage tank that can contaminate surrounding soil, groundwater, or surface waters, or affect indoor air spaces.

Suspected releases include:

- Unusual operating conditions observed by owners and operators (such as the erratic behavior of product dispensing equipment, the sudden loss of product from the UST system, an unexplained presence of water in the tank, or liquid in the interstitial space of secondarily contained systems).

- Monitoring results, including investigation of an alarm, from a release detection method that indicate a release may have occurred.

When these conditions occur, owner operators investigate and confirm whether a release has occurred by carrying out system tests or by taking samples where the release most likely occurred (e.g., near a faulty dispenser or along a suspected line leak). If a release is confirmed, it must be reported, and appropriate abatement measures taken.

Confirmed releases include:

- The discovery by owners and operators or others, including the implementing agency, of released regulated substances at the UST site or in the surrounding area (such as the presence of free product or vapors in soils, basements, sewer and utility lines, and nearby surface water or drinking water).

- A spill or overfill of petroleum that results in a release to the environment that exceeds 25 gallons, or another reasonable amount specified by the implementing agency, or that causes a sheen on nearby surface water.

|

If in doubt on who to contact, call Emergency Services and the National Response Center at 1-800-424-8802 |

When any of these conditions occur, the owner or operator must report the event to the implementing agency within 24 hours.

Contact your implementing agency regarding particular state or tribal requirements:

- States: Underground Storage Tanks state contacts.

- Indian Country.

Initial Response (40 CFR Part 280.61) and Check site and take initial abatement actions (40 CFR 280.62)

Take immediate action to stop and contain the release.

Report the release to the implementing agency within 24 hours. However, petroleum spills and overfills of less than 25 gallons do not always have to be reported if you immediately contain and clean up these releases and document them.

In some cases, emergency response actions must be taken immediately without waiting for government approval or oversight. Initial actions are all focused on protecting public health, safety, and the environment. Make sure the release poses no immediate hazard to human health and safety by removing explosive vapors and fire hazards. Your fire department should be able to help or advise you with this task. You must also make sure you handle contaminated soil properly so that it poses no hazard (for example, from vapors or direct contact).

Remove petroleum from the UST system if necessary to prevent further releases into the environment. Find out how far the petroleum has moved and begin to recover the leaked petroleum (such as product on the water table in a well or excavation). Report your progress and any information you have collected to your implementing agency no later than 20 days after confirming a release.

Investigate to determine if the release has damaged or might damage human health and the environment. This investigation should determine the extent of contamination both in soils and ground water to the level of accuracy required by your implementing agency. You must report to the regulatory authority what you have learned from the investigation of your site according to the schedule established by the implementing agency. Additional site studies may be required.

Remove Free Product/LNAPL Recovery (40 CFR 280.64)

When pure gasoline or fuel is detected in groundwater after a new release, the product needs to be recovered quickly and efficiently. The longer that mobile or migrating free product stays in the ground, the greater the chance of migration into utilities, drinking water wells, or indoor spaces.

The Free Product Removal regulation at 40 CFR 280.64 requires owners and operators to remove free product. Owners, operators, and regulators have asked for clarification on free product removal under this section of the federal regulations.

EPA does not consider that 40 CFR 280.64 requires removal of all measurable free product. EPA considers that the objective of 40 CFR 280.64 is the removal of free product to prevent migration. 40 CFR 280.64(a) requires “free product removal in a manner that minimizes the spread of contamination into previously uncontaminated zones by using recovery and disposal techniques appropriate to the hydrogeologic conditions at the site” while 40 CFR 280.64(b) specifies the “abatement of free product migration as a minimum objective for the design of the free product removal system.”

The federal regulation was written to require owners to remove free product during the early phases of a response to a confirmed release. EPA’s intention was to mitigate the risk of free product spreading to uncontaminated areas of a site. EPA’s comments and responses to the Proposed Rule and the preamble discussion to the Final Rule make this intention clear (see epa.gov/ust/preambles-1988-ust-regulations-40-cfr-parts-280-and-281).

The intention to mitigate risk to human health and the environment from petroleum releases remains the same, but our understanding about the mobility and behavior of petroleum underground has increased significantly in the 35 years since promulgation of 40 CFR 280.64. As a result, the term “Free Product” has evolved to a more granular classification of Light Non-Aqueous Phase Liquids. Well-established and widely recognized definitions are provided below.

- LNAPL - A light non-aqueous phase liquid (e.g., petroleum oil, gasoline, diesel fuel) that has a density less than water and is immiscible with water.

- Residual - LNAPL that is bound in the soil and will not move into monitoring wells or smear with a rising or falling water table.

- Mobile - LNAPL that exists above residual saturation levels such that it can accumulate in monitoring wells constructed within its footprint or smear vertically with a rising or falling water table but will not migrate or spread from its current footprint (i.e., move into monitoring wells beyond its current footprint).

- Migrating - A LNAPL body that is expanding laterally into areas previously not impacted by LNAPL.

UST Sites may have “migrating LNAPL” as well as “mobile LNAPL” and “residual LNAPL.” Mobile and residual LNAPL are both distinct from migrating LNAPL in that they do not spread laterally and do not increase the LNAPL footprint. Abatement of mobile and residual LNAPL is not necessary to meet the requirement of 40 CFR 280.64 to prevent the migration of “free product” into previously uncontaminated soil or groundwater. All forms of LNAPL are subject to the assessment and remediation requirements of 40 CFR 280.65 and 280.66, requiring owners and operators to take actions to assess and remediate as deemed necessary by the implementing agency to protect human health and the environment.

The Interstate Technology Regulatory Council LNAPL-3 guidance provides detailed technical information about the three types of LNAPLs as well as a comprehensive framework for developing remediation approaches, technologies, and goals. OUST recommends that implementing agencies consider the approaches to assessing and remediating migrating, mobile, and residual LNAPL described in ITRC’s LNAPL-3.

Implementing agencies have the discretion to develop criteria for determining the presence of free product/migrating LNAPL and the extent of its removal. Sites that have measurable LNAPL after the initial removal typically require investigation to assess the need for soil and groundwater cleanup under 40 CFR 280.65. Implementing agencies may also require owners and operators to submit a Corrective Action Plan that identifies the need for LNAPL remedial action beyond free product removal (40 CFR 280.66). The Corrective Action Plan should include an assessment as to whether mobile and residual LNAPL remediation is necessary to prevent further groundwater contamination and vapor intrusion risks.

Site Characterization (40 CFR 280.63 and 280.65)

Site characterization is the process by which site-specific information and data are gathered from a variety of sources to characterize the physical, biological, and chemical systems at a contaminated site. Site characterization allows the development of the conceptual site model and the use of risk-based decision making.

Site characterization is also called site investigation or site assessment and can be as simple as a site inspection or can involve extensive soil and groundwater sampling. The implementing agency will advise on the extent of investigation required.

Under the federal UST regulations, an initial site characterization is required to assess the nature and estimated quantity of release; and to provide information on surrounding populations, water quality, use and approximate locations of wells potentially affected by the release, subsurface soil conditions, locations of subsurface sewers, climatological conditions, and land use (40 CFR 280.63);

Site characterization can include soil, groundwater, and soil gas sampling. Samples need to be analyzed for contaminants of concern for the type of petroleum released from the source. A site characterization should identify at-risk receptors, determine whether recoverable free product is present, and determine if any groundwater plume is increasing in size or is stable and reducing. Site characterization should include an assessment of the geology of the site and the pathways through which contaminants might flow. The depth to groundwater, its seasonal fluctuations, and the direction of groundwater flow needs to be determined.

Further site characterization is necessary to characterize the extent of contamination in soil and groundwater under 40 CFR 280.65 where:

- There is evidence that groundwater wells have been affected by the release (e.g., as found during release confirmation or previous corrective action measures).

- Free product is found to need recovery.

- There is evidence that contaminated soils may be in contact with groundwater.

- The implementing agency requests an investigation, based on the potential effects of contaminated soil or groundwater on nearby surface water and groundwater resources.

EPA encourages the use of high resolution site characterization to rapidly identify contaminant location and assist in developing a complete conceptual site model.

Resources

EPA

Site Characterization Fundamentals

- Modeling Subsurface Petroleum Hydrocarbon Transport

OnSite is an EPA ORD website with a collection of tools for site assessment that contains calculators for: formulas, models, unit conversion factors, and scientific demonstrations to assess the impacts from groundwater contaminants. - Site Characterization for Subsurface Remediation (EPA 625-4-91-026) November 1991

Seminar publication from EPA on site characterization for subsurface remediation, focusing on fundamental geologic, hydrogeologic and geochemical fundamental concepts in environmental site characterization. - Best Practices for Environmental Site Management: A Practical Guide for Applying Environmental Sequence Stratigraphy to Improve Conceptual Site Models (EPA/600/R-17/293) (62 pp, 3.6 MB) .

- Assessing and remediating low permeability geologic materials contaminated by leaking underground storage tanks: a literature review.

- Expedited Site Assessment Tools for Underground Storage Tank Sites: A Guide for Regulators (EPA 510-B-97-001) March 1997

EPA guidance document on the expedited site assessment process, a framework for rapidly characterizing UST site conditions for corrective action decisions (also known as accelerated site characterization, rapid site characterization, and expedited site investigation). - Triad Issue Paper: Using Geophysical Tools to Develop the Conceptual Site Model.

Website Collections

- Clu-in: Characterization and Monitoring Technologies EPA website on characterization and monitoring that contains links to information on technology tools, statistics and sampling design, sample collection and handling, environmental data quality, and other topics.

- Triad Resource Center.

- UST Training.

ITRC

- Implementing Advanced Site Characterization Tools.

- Characterization and Remediation in Fractured Rocks.

- Integrated DNAPL Site Characterization and Tools Selection.

- Mass Flux.

API

Groundwater Plume Visualization Software GWSDAT.

High Resolution Site Characterization

High-resolution site characterization strategies and techniques use scale-appropriate measurements and sample density to define contaminant distributions, and the physical context in which they reside, with greater certainty, supporting faster and more effective site cleanup.

HRSC is widely used at large, complex release sites to identify the contaminant mass in soil and groundwater, including LNAPL and provide a detailed geologic profile of soil zones that are storing and transmitting contaminants. High-resolution technologies and sampling approaches are described in detail in ITRC’s LNAPL3, petroleum vapor intrusion, advanced site characterization, and fractured bedrock guides, and in other guidance.

The majority of petroleum UST release sites, however, continue to be assessed using traditional monitoring well investigation techniques. Traditional monitoring well investigations are less capable of identifying discrete zones of contamination and thin zones of contaminant transport and storage and may therefore be less able to provide the data required to develop conceptual site models that allow the design of remediation system that directly treat contaminated zones. Discrete pathways that may allow contaminants to threaten points of exposure may not be fully identified and characterized.

HRSC is a “measure twice, cut once” approach that may reduce overall cleanup costs, even where initial costs may create a perception that HRSC is more expensive than traditional approaches.

The data generated by the HRSC approach is often more detailed and comprehensive than traditional monitoring well investigations can yield, which allows for the creation of more complete conceptual site models, clearer communication with the stakeholders, more informed remediation decisions, quicker site closures, lower overall remediation costs, and ultimately, better protection of human health and the environment. Generating data on site and allows prompt decision making and fewer mobilizations and stages of site characterization.

Data collected via HRSC methods may need to be supplemented with data from conventional investigation techniques (e.g., discrete soil or groundwater samples may be required for regulatory decisions). Relying solely on conventional techniques is no longer considered best practice.

HRSC methods have been used successfully for many years and on thousands of sites, including hundreds of petroleum release sites, both big and small and there appears to be an opportunity to improve environmental protection and save time and money by expanding the use of HRSC in petroleum UST release sites.

In 2022 EPA’s Office of Underground Storage Tanks worked with EPA's Office of Communications, Partnerships and Analysis and its economics consultant, IEc to evaluate the role of HRSC in petroleum UST release corrective action and whether encouraging its use was warranted. By interviewing states, consultants and practitioners, EPA found that HRSC was useful in many situations where additional information was needed to develop the conceptual site model. The study also found that HRSC was likely to reduce overall project costs and the time to case closure in many cases.

Resources

LUSTline stories on HRSC

Clu-in High Resolution Site Characterization Resources

Expedited Site Assessment Tools for Underground Storage Tank Sites: A Guide for Regulators (EPA 510-B-97-001) March 1997 to 2016

EPA guidance document on the expedited site assessment process, a framework for rapidly characterizing UST site conditions for corrective action decisions (also known as accelerated site characterization, rapid site characterization, and expedited site investigation.).

ITRC

- Implementing Advanced Site Characterization Tools (ASCT)

- Characterization and Remediation in Fractured Rocks

- Integrated DNAPL Site Characterization and Tools Selection

- Mass Flux

Conceptual Site Models

Site characterization is the process by which site-specific information and data are gathered from a variety of sources to characterize the physical, biological, and chemical systems at a contaminated site. A conceptual site model (CSM) integrates all lines of evidence into a three- dimensional picture of site conditions that illustrates contaminant distributions, release mechanisms, migration routes, exposure pathways, and potential receptors. The CSM uses a combination of text and graphics to portray both known and hypothetical information. The CSM documents current site conditions and is supported by maps, cross-sections, and site diagrams that illustrate human and environmental exposure through contaminant release and migration to potential receptors. Frequently, a CSM may be presented as a site map and/or developed as a flow diagram which describes potential migration of contaminants to sit. The CSM synthesizes data acquired from historical research, site characterization, and remediation system operation.

CSM development continues throughout the lifetime of a project as new information is obtained. The CSM guides risk-based decision making (RBDM), site characterization activities, corrective action design and selecting remedial objectives. The CSM evolves from the first day of the release investigation to the eventual closure of the case as additional information is gathered and interpreted. The CSM can address:

- Inventory records or data from electronic inventory systems that can be used to estimate the source, quantity, and timing of the piping, tank, or system failure.

- The location of the leak and the horizontal and vertical extent of the source area must be understood as required by the implementing agency.

- Characteristics of a site, such as geology and hydrology, are used to create the CSM, which guides the collection of data in the site characterization and the type and amount of required cleanup.

- Potential exposure pathways associated with petroleum contamination include water supplies, indoor air (petroleum vapor intrusion), construction worker exposures, migration along storm drains and other underground utilities and impacts to surface water environments. Receptors, such as drinking water supplies, sensitive wetlands or surface waters, schools, day-care facilities, hospitals, and residences should be identified and potential pathways to these receptors investigated.

Current understanding of soil, groundwater and contaminant movement is that storage and transmission of contaminants and water is often highly heterogeneous. Contaminant storage and transportation often occurs in a small proportion of a particular geologic unit. Investigation to understand how this is occurring may need the use of precision tools providing real-time results. High resolution site characterization tools provide a means of gaining the data necessary to develop a CSM that reflects real life heterogeneity.

Resources

- Environmental Cleanup Best Practices-Effective Use of the Project Cycle Conceptual Site Model.

- Clu-in Conceptual Site Model check list.

- ASTM E1689 - 20 Standard Guide for Developing Conceptual Site Models for Contaminated Sites.

Risk Based Decision Making and Underground Storage Tanks

EPA encourages the use of risk-based decision making that allows site specific target levels to be developed ensuring each cleanup is protective of human health and the environment and to allow timely and appropriate use and reuse of LUST sites.

RBDM considers the current and potential risks posed by an UST release to identified human health and environmental receptors and evaluates appropriate methods to mitigate those risks. RBDM can:

- Focus site assessment and data collection on receptors and likely contaminant pathways.

- Prioritize sites for cleanup.

- Determine appropriate initial responses.

- Establish cleanup goals.

RBDM is integral to timely and complete cleanups addressing human health and the environment. RBDM can only be properly used for cases where an appropriate conceptual site model has been developed for the release. Developing an appropriate CSM should be part of all cleanup investigations.

In March 1995 EPA issued a comprehensive policy, Directive 9610.17, that explains the use of risk-based approaches at UST sites. EPA works with its regional offices and with state and local UST programs to encourage the use of RBDM in their corrective action programs. States are the primary implementers of the UST program outside of Indian Country. Check with your state agency to see if they use RBDM and to find out the specifics of their program.

Resources

RBDM Technical Support Documents

- ITRC Risk Assessment Resources.

- ITRC Decision Making at Contaminated Sites.

- RBCA Fate and Transport Models: Compendium and Selection Guidance (PDF) (138 pp, 6.9 K, About PDF).

- ASTM E1739 Standard Guide for Risk-Based Corrective Action Applied at Petroleum Release Sites Note that industry codes and standards are copyrighted and are available only from the developing organization. These codes and standards must be purchased directly from the developing organization.

Corrective Action (40 CFR 280.66)

Under 40 CFR Subpart F 280.66, a corrective action plan is required when action is necessary to adequately protect human health and the environment and should consider:

- (1) The physical and chemical characteristics of the regulated substance, including its toxicity, persistence, and potential for migration.

- (2) The hydrogeologic characteristics of the facility and the surrounding area.

- (3) The proximity, quality, and current and future uses of nearby surface water and groundwater.

- (4) The potential effects of residual contamination on nearby surface water and groundwater.

- (5) An exposure assessment. And,

- (6) Any information assembled in compliance with this subpart.

The conceptual site model along with acceptable risk factors, cost, local policies, available technologies, and community input will all help determine the appropriate cleanup method to apply to a leaking underground storage tank site. EPA encourages the use of Risk-based decision-making to develop appropriate remedial targets, to identify the appropriate type of cleanup action, and to assess the degree of urgency based on human and environmental receptors.

The Corrective Action objectives at a LUST site may include ensuring that threats to identified receptors are prevented, that targeted concentration for specific contaminants are reached, or that residual contamination is stable and decreasing, and natural degradation is occurring.

After a thorough analysis of the CSM and selection of cleanup goals, the most appropriate corrective action options (e.g., excavation and removal, enhanced hydraulic recovery, or soil-vapor extraction) should be identified and described in a corrective action proposal. The technologies should undergo a thorough analysis from both a technical and cost perspective. An evaluation report that summarizes the benefits and drawbacks of each alternative is usually prepared for review by government agencies. A pilot test may be necessary to determine the effectiveness of the selected remedy prior to full scale application. Once the review of alternatives is completed, a specific corrective action or set of actions is selected and implemented.

In many cases, a “treatment train” of several remedial technologies will be required at different stages of the corrective action to achieve the final cleanup objectives. Identifying corrective action implementation performance objectives for each component of a remediation “treatment train” is important.

The selected remedial action is described in detail in the corrective action plan and may include written specifications and detailed engineering drawings. The plan should include specific cleanup goals, how progress will be measured, a project schedule, and project milestones.

Any confirmed release that requires a Corrective Action Plan also requires public participation. After considering public comments the implementing agency typically documents the approved CAP.

Resources

A Guide for Corrective Action Reviewers

CLU-IN Remediation Technologies

EPA website that includes links to information on remediation technologies, project and site profiles, case studies, a technology screening matrix, newsletters, and how to select an innovative cleanup technology.

CLU-IN Green Remediation Focus

EPA website on green remediation that provides links to policies and strategies, incorporating best management practices, green remediation in the news, and more.

Corrective Action Plan Public Participation (40 CFR 280.67)

Under 40 CFR 280.67 “For each confirmed release that requires a corrective action plan, the implementing agency must provide notice to the public by means designed to reach those members of the public directly affected by the release and the planned corrective action.” Implementing agencies determine the type of public notice and public participation for their community.

Public participation can include activities such as notice to local municipal or county officials, notices in the local newspaper or public hearings to provide a forum for parties who may be impacted by the corrective action. If holding public hearings are appropriate, they should be scheduled at a time and place convenient to the affected public.

Notice to the public is not required when a formal corrective action plan is not required by the implementing agency (for example, if a case is resolved at the initial response or investigation stages).

Resources

EPA

Community Engagement and the Underground Storage Tank Program

RCRA Public Participation Manual-Tools

ITRC

Corrective Action Implementation (40 CFR 280.66(c))

40 CFR 280.66(c) requires that “upon approval of the corrective action plan or as directed by the implementing agency, owners and operators must implement the plan, including modifications to the plan made by the implementing agency. They must monitor, evaluate, and report the results of implementing the plan in accordance with a schedule and in a format established by the implementing agency.”

Performance monitoring and evaluation should assess progress toward achieving the cleanup objectives. Performance monitoring approaches will vary depending on the situation but typically include evaluating the remedial technology performance and assessing conditions at identified compliance points, whether groundwater monitoring wells, surface water, or soil gas. In many cases, achieving remedial objectives requires the use of complementary, successive, technologies at different stages of the corrective action, often described as a “treatment train.” Performance monitoring should be done to determine the performance of a particular technology and when it has reached the point of diminishing returns. At this point, it may be appropriate to use an alternative technology to achieve the corrective action objectives.

Resources

EPA

A Guide for Corrective Action Reviewers

Clu-in

A Citizen’s Guide to Monitored Natural Attenuation

ITRC

Remediation Process Optimization

Optimizing Injection Strategies and In-situ Remediation Performance

Geospatial Analysis for optimization at environmental sites

NAVFAC

Case Study Review of Optimization Practices at Navy Petroleum Sites (SEP 2021)

Greener Cleanups at LUST sites

EPA recommends implementing greener cleanup approaches at all phases of the LUST corrective action process, from investigation to closure.

Resources

CLU-IN Green Remediation Focus

EPA website on green remediation that provides links to policies and strategies, incorporating best management practices, green remediation in the news, and more.

Green Remediation Best Management Practices: Sites with Leaking

Underground Storage Tanks fact sheet.

ITRC Sustainable Resilient Remediation

A Guide for EPA Regions on Planning LUST Cleanups in a Changing Climate (pdf)

A Guide for EPA Regions on Planning LUST Cleanups in a Changing Climate (docx)

L.U.S.T.Line articles --

How can Tank Programs get on the ball with sustainability?

Let’s Talk “Green” at LUST sites (LUSTLINE Bulleting 75 page 16)

Institutional and Engineering Controls

Institutional controls are administrative and legal controls that help minimize the potential for exposure to contamination and protect the integrity of the remedy. ICs can play an important role in reducing exposure to contamination by limiting land or resource use and guiding human behavior at a site. For instance, zoning restrictions prevent site land uses that are not consistent with the level of cleanup, such as prohibiting residential use on land remediated to an industrial standard. Soil management plans are sometimes needed where shallow contamination remains where future excavation is anticipated.

Engineering controls are typically physical barriers that limit or restrict exposure to contamination both in the short term and for extended future use. Institutional controls are often used in conjunction with engineering controls. Institutional and engineering controls should have a mechanism to ensure they continue to be maintained and enforced.

Resources

EPA

Institutional Controls: A Guide to Planning, Implementing, Maintaining, and Enforcing Institutional Controls at Contaminated Sites

Implementing Institutional Controls in Indian County

Institutional Controls: A citizen’s guide to Understanding Institutional Controls at Superfund, Brownfields, Federal Facilities, Underground Storage Tank, and Resource Conservation and Recovery Act Cleanups

Long Term Stewardship at Leaking Underground Storage Tank Sites with Residual Contamination

Use of Advanced Monitoring Technologies and Approaches to support long term stewardship

ITRC

Long Term Contaminant Management Using Institutional Controls

Remediation Closure or No Further Action

Remediation closure is a milestone achieved when the implementing agency determines that the remaining contamination in the soil, surface water, groundwater, or soil gas no longer poses a significant risk to human health or the environment. Remediation closure is often referred to as “no further action.”

The end point of a corrective action at a LUST site may include reaching a targeted concentration for specific contaminants or demonstrating that remaining residual contamination is stable and decreasing or confirming that threats to identified receptors are low and natural degradation is occurring.

Implementing agencies typically reserve the right to reopen cases where new information indicates further investigation, remedial action, or renewal of institutional and engineering controls is necessary to ensure that human health and the environment remains protected. Some implementing agencies have long-term stewardship or post closure reviews procedures to ensure closed cases remain protective of the environment.

Long-Term Stewardship and Post Closure Reviews

Implementing agencies can use a range of techniques to ensure closed cases remain protective of human health and the environment over time and with changes in land use. Post closure review can increase confidence that sites that were closed with residual contamination remain protective over the long term. Post closure reviews are generally conducted periodically (for example, every five years) and could incorporate one or more long-term stewardship practices, such as the review of the continued effectiveness of institutional and engineering controls, land use planning controls, building permit controls, groundwater well permits and, potentially, post closure monitoring of selected sentinel wells.

Resources

ITRC -- Long Term Contaminant Management Using Institutional Controls

Petroleum Contaminants to consider in LUST cleanups

Contaminants released into the environment from fuel releases vary as different fuels have different chemical compositions. Older fuels may have included contaminants of concern not typically found in recent releases. Once a fuel is released into the environment, its composition changes -- some components may biodegrade, some may dissolve into solution, and some may volatilize. Depending on the history of the release and the nature of the fuel, contaminants to consider may include:

- BTEX -- Benzene, toluene, ethylbenzene, and xylene for gasoline releases.

- Polyaromatic hydrocarbons (particularly naphthalene) for diesel and other heavier grade fuels.

- Total petroleum hydrocarbons, analyzed for the carbon chain range relevant to grade of fuel.

- Fuel additives:

- Fuel Oxygenates MTBE - Methyl tert-butyl ether, TBA - tert-Butyl alcohol, TAME - tert-Amyl methyl ether, and ETBE - Ethyl tert-butyl ether were included in gasoline produced until the early 2000s.

- Lead scavengers and anti-knock agents such as 1,2-Dichloroethane (DCA) and Ethylene Dibromide (EDB) added to leaded fuels. Leaded fuels were widely used before 1976 when unleaded fuels became available and were banned (except for airplane use) in 1996. In 2010 EPA OUST issued a memo on the investigation and remediation of lead scavengers.

- Ethanol in gasoline produced since the 2000s. Ethanol typically rapidly degrades when released into the subsurface environment so is rarely detected beyond the immediate area of the release source when released as an additive in gasoline.

Resources

Petroleum Vapor Intrusion

Petroleum vapor intrusion occurs when volatile petroleum hydrocarbons such as gasoline, diesel, or jet fuel leak (or additives and their degradation products, such as methane) into the subsurface and create a source of petroleum vapors that can enter a building. The intrusion of contaminant vapors into indoor spaces is of concern due to threats to safety (e.g., explosive concentrations of petroleum vapors or methane) and possible adverse health effects from long term inhalation exposure to chemicals in the petroleum vapor. Many of the chemicals of concern in petroleum vapor are also present in most building and furnishing materials, so investigations of long-term petroleum vapor intrusion risks should initially focus on the potential presence of subsurface vapor.

Resources

EPA

Technical Guide for Addressing Petroleum Vapor Intrusion at Leaking Underground Storage Tank Sites

PVIScreen -- EPA developed a model to assess the potential for petroleum vapor intrusion into nearby buildings from leaking UST sites. Modeling results may help regulators determine when sites can be screened out form further investigation. March 2018 90-minute webinar about EPA's PVIScreen model. Dr. James Weaver of EPA-ORD gives an overview of the model and demonstrates how to use it.

PVI Background Information EPA gathered an extensive bibliography of papers and studies on petroleum vapor intrusion science, sampling, and mitigation.

ITRC

Petroleum Vapor Intrusion guidance on assessment and management

ITRC Vapor intrusion mitigation guidance