Water Reuse Case Study: Quincy, Washington

EPA and partners have created a series of case studies that highlight the different water reuse approaches communities have taken to meet their water quality and water quantity needs. Each case study contains information about the technical, financial, institutional, and policy aspects of these water reuse systems and the communities they are located in.

On this page:

- Overview

- Context

- Solution

- Policy, Institutional, and Regulatory Environment

- Financial and Contractual Agreements

- Benefits

- Lessons Learned and Conclusions

- Background Documents

Location: Quincy, Washington

Demand Offset: 138 million gallons per year (522 million liters per year)

Status: Operational since 2021

Overall Cost: $31 million

Source of Water: Industry process water (cooling water)

Reuse Application: Industrial processes (data center cooling)

Benefits: Reduced reliance on surface and groundwater supply, improved water supply for data center cooling operations, fewer issues associated with the use of high mineral-content groundwater for cooling

Overview

Microsoft and the City of Quincy partnered to construct the Quincy Water Reuse Utility, which treats cooling water from a Microsoft data center and recirculates it to the data center for the same purpose, reducing reliance on local potable groundwater. The local groundwater also has high levels of total dissolved solids, which can cause problems when used in the data center’s cooling equipment. The water supplied from the Quincy Water Reuse Facility is of a more suitable quality for the data center’s cooling equipment than the conventionally treated, mineral-rich groundwater. Therefore, water recycling helps to lower the use of potable groundwater supplies in the region while supplying cooling water of a higher quality to the Microsoft data center.

Related Links

Context

The City of Quincy is in the arid eastern part of the State of Washington and receives only 7.8 inches (199 millimeters) of annual rainfall. Five groundwater wells provide all of the potable water to service residential, commercial, and industrial needs within the city. The wells reach depths up to 1,000 feet (305 meters) into the Columbia Plateau regional aquifer system, which is mostly made up of basaltic rocks. While the residential part of town is relatively small (about 8,100 people), Quincy’s large industrial sector means its water demand is akin to that of 30,000 inhabitants. Quincy has a large food processing industry and houses data centers belonging to several companies, including Microsoft, Yahoo, Sabey, Intuit, and Vantage. Quincy is an attractive area to build these data centers because of the area’s affordable land (as compared to land in the Silicon Valley region of California), cool ambient temperatures, and the availability of renewable electricity from hydropower. There is also a substantial amount of agricultural activity in the area around Quincy.

Water Usage and Needs

Typically, the city uses around 2.1 billion gallons (8 million liters) of groundwater per year. Until recently, 57 percent of the pumped groundwater was used by food processors; 33 percent went to residents and public or commercial services such as schools, hotels, or restaurants; and the remaining 10 percent was used by data centers for cooling purposes.

Since 2007, Microsoft has operated one of the biggest data centers in Quincy on a 270-acre (110-hectare) campus. The large volume of water needed to cool high-density cloud computing server farms is making water management a growing priority for data center operators, including Microsoft. In the past, Microsoft received potable groundwater from Quincy for cooling; after four to five cooling cycles they would discharge the water to the sewer system for treatment at the city’s municipal wastewater reclamation facility. However, this water was rich in minerals including calcium, magnesium, and silica. The high mineral content meant that long water cycles in the data centers could damage heat transfer equipment, or generally impair heat transfer, as water evaporated during cooling and the concentration of total dissolved solids (TDS) increased. To mitigate this mineral buildup, the water had to be drained from the cooling equipment and treated more often. Such water is called “blowdown” water or “bleed” water.

Original Wastewater Treatment Approach

The city already had a municipal wastewater reclamation facility (MWRF) that uses reclaimed water to irrigate public areas and to recharge shallow aquifers in the area through groundwater recharge basins. However, discharges from regional data centers to the MWRF were problematic due to high TDS concentrations, which the MWRF was not designed to treat. The data centers were charged an extra fee to accommodate adjustments to the facility’s process and increased maintenance needs. The high levels of TDS, calcium, magnesium, and silica also created a visible cake on the surface of the groundwater recharge basins in the summer, which was causing it to exceed discharge and indirect potable reuse requirements, e.g., for aquifer recharge, set by the Washington State Department of Ecology.

Solution

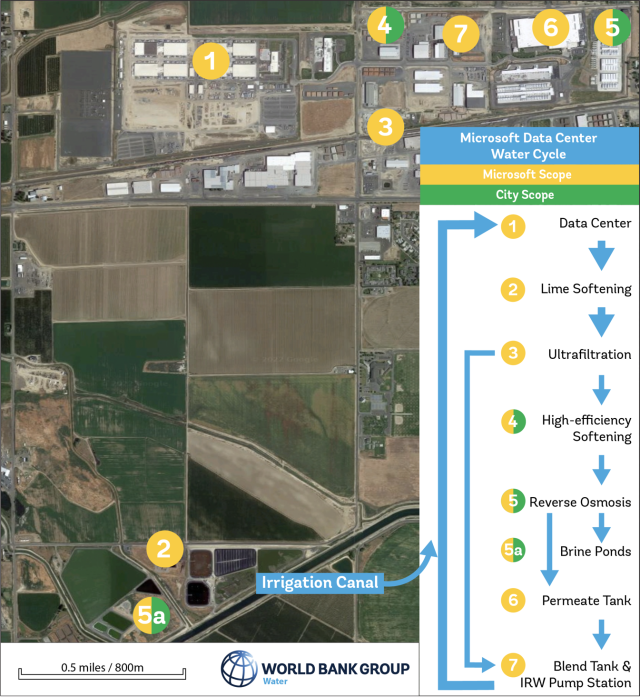

The City of Quincy and Microsoft both recognized the technical difficulty of using mineral-rich municipal groundwater for cooling data center equipment, as well as the subsequent challenge of treating the data center’s industrial wastewater with high levels of TDS at the city’s municipal wastewater reclamation facility. The city and Microsoft partnered to create the Quincy Water Reuse Utility (QWRU), an entirely new facility specifically designed to treat the cooling water from Microsoft’s data center. After more than 10 years of planning and construction, the QWRU officially became operational on June 30, 2021. It is comprised of 10 distinct treatment systems connected by over 30 miles (48 kilometers) of pipes across Quincy’s industrial area. As of 2022, only Microsoft’s data center campus was connected to the QWRU.

Because the QWRU is a closed-loop system, it does not discharge industrial wastewater with high mineral content to the environment, nor does it discharge industrial wastewater to the city’s MWRF. However, to prevent mineral buildup in the cooling water, salts are removed from the water prior to reuse at the data center and concentrated in lined brine ponds to form a solid which is disposed of in a manner that prevents entry into state ground or surface waters. This ensures that the cooling water quality does not adversely affect cooling equipment or heat transfer within the data center. Equally important, the QWRU substantially reduces the data center’s reliance on potable groundwater for data center cooling, saving an estimated 138 million gallons of water per year (522 million liters per year) through the water reuse treatment system.

Treatment System Description

The QWRU relies on a combination of:

- Newly constructed systems, including a lime softening facility, an ultrafiltration facility, a permeate tank facility, a blend tank facility storage, and brine ponds.

- Previously existing infrastructure which was part of the city’s industrial wastewater treatment systems, including a high-efficiency softening (HES) facility and reverse osmosis (RO) plant.

After the water is cycled four to five times at the data center, the resulting blowdown water is transferred to a lime softening facility that adds limewater (calcium hydroxide) to remove hardness (deposits of calcium and magnesium salts). It then flows to an ultrafiltration facility.

After ultrafiltration, some of the water is transferred to a blend tank, while the rest is further softened in the HES facility and filtered at the RO plant. A pipe transfers the HES brine (rich in calcium and magnesium) and the RO brine (rich in silica) to brine ponds. The brine undergoes maximum evaporation, and the residuals are disposed of separately; Quincy expects it will need to do this every two or three years.

The treated industrial wastewater that has passed through the RO treatment system is stored in a permeate tank for about eight hours. This functions as a buffer in case of downtime due to maintenance of any of the HES or RO systems. The RO and ultrafiltration water are blended at various ratios throughout the day depending on the conductivity levels (target range: 300–350 microsiemens). Afterward, the treated industrial wastewater is returned to the data center for use as cooling water.

Make-up Water Sources

The QWRU system is topped up regularly because water evaporates during the cooling process and a small volume of highly concentrated brine needs disposal. Since data centers do not need potable water for cooling, Microsoft and the City of Quincy have been able to use make-up water from untreated surface water sources by accessing rights to water drawn from the Columbia Basin Project in the U.S. Bureau of Reclamation and the Quincy Irrigation District canal.

The QWRU uses 260 million gallons per year (984 million liters per year) of Columbia Basin Project water from the irrigation canal primarily during the summer, when cooling demand in data centers is highest. This substantially lowers the need to use groundwater for cooling and reduces the city’s potable water demand and treatment costs because there is no need to soften the water before sending it back to the data center. The irrigation canal, where the water is extracted, runs dry in winter—but this is not a significant issue, since cooling demand is comparatively lower in the winter months.

On an annual basis, 5 percent of the make-up water is still potable groundwater, which is mixed and softened before entering the cooling systems. Going forward, the City of Quincy aims to purchase more water from the Bureau of Reclamation and get permission from the Quincy Irrigation District to withdraw more water from the canal because it requires minimal treatment for the data centers and could eliminate the data center’s reliance on potable groundwater supplies.

Policy, Institutional, and Regulatory Environment

The State of Washington has a comparatively long history of considering water as part of the circular economy and encouraging water recycling. In 1992, the Washington State Legislature passed the Reclaimed Water Act to encourage beneficial reuse of treated municipal wastewater while ensuring the health and safety of all Washington citizens and the protection of its environment. Respective standards and regulations were developed by the Department of Health and the Department of Ecology. In 2018, Washington State promulgated a reclaimed water rule that streamlined the reclamation process and ensured that reclamation projects protect water quality and public health.

Washington has regulations for indirect potable water reuse and several non-potable reuse applications, including landscaping, agriculture, centralized non-potable reuse, impoundments, and environmental restoration. More details on Washington’s and other state’s water reuse regulations can be found in the EPA’s REUSExplorer tool.

Managing TDS Levels in Municipal Wastewater Effluent

One regulatory driver for this project was the TDS limits set by the municipal wastewater reclamation facility discharge permit issued by the Washington State Department of Ecology. Groundwater recharge using treated municipal wastewater is regulated under the state’s indirect potable water reuse regulations, as the groundwater is expected to eventually be a source of drinking water for the public. While the initial discharge permit at the MWRF did not require testing for TDS, the city began to voluntarily sample TDS in MWRF influent and effluent in 2007, fourteen years prior to the construction of the QWRU. During this time, when the MWRF was still accepting a significant amount of industrial wastewater from the data centers, the city reported TDS test values for both influent and effluent consistently above the Department of Ecology’s groundwater guideline of 500 milligrams per liter, which was a concern because some treated effluent from the MWRF was used for recharging the local aquifer. To meet indirect potable reuse requirements, the MWRF would have needed to make continuous, costly operational modifications because its treatment process was not designed to receive cooling water with such high TDS concentrations.

With the city’s test results for TDS exceeding the groundwater guideline, the Department of Ecology urged the city to address the issue. The Department of Ecology granted the city a grace period to be able to construct the separate treatment system specifically for blowdown water from the data centers which would allow the MWRF to meet the groundwater permit TDS limits. The city constructed a separate industrial wastewater treatment plant which allowed the cooling water blowdown from the data centers to be processed separately from the city’s municipal wastewater. Eventually, the city’s industrial wastewater treatment plant became a key component of the QWRU. Now, water from the industrial wastewater treatment plant is reused because construction of the QWRU involved treating the industrial wastewater treatment plant’s effluent. Therefore, the operation of the QWRU and the city’s industrial wastewater treatment plant allows Quincy to sustainably pursue two forms of water reuse: 1) recycling of data center cooling water through the QWRU itself and 2) sustaining the city’s reuse of treated municipal wastewater effluent from its MWRF for indirect potable water reuse and irrigation of public spaces.

Geographic Considerations

Because QWRU is on the west side of Quincy, it is expensive for data centers on the eastern side to connect to it; instead, they still use potable groundwater for cooling. The City of Quincy is actively exploring other solutions for these data centers. As of early 2023, the city officials preferred not to publicly disclose options under consideration.

Permits

The industrial wastewater treatment plant permit for sludge and brine management, issued by the Washington State Department of Ecology, is applicable to the QWRU. This permit defines the additional disposal management of residuals (salts and contaminants that have been removed from the water) for Quincy’s different treatment facilities, including the QWRU.

The QWRU would need additional discharge-related permits if its treated industrial wastewater were to be used for any purpose other than industrial use. If it were discharged to surface water or groundwater, it would need to comply with applicable state standards. However, at present, the QWRU system does not discharge any wastewater besides a small volume of residuals to the evaporation brine ponds. The vast majority of the treated blowdown water is combined with make-up water and recirculated back to the cooling towers.

Financial and Contractual Agreements

Quincy and Microsoft signed a 30-year agreement to finance and operate the QWRU. The agreement stipulated that the city would own and operate the QWRU, but Microsoft would entirely finance the capital investments and related costs ($31 million) to build the new infrastructure for it, as well as all operational costs. The agreement between Microsoft and the city also includes flexible provisions such as regular adjustment of the rates paid by Microsoft.

The initial investment was made through a multiple-revenue bond between Quincy and Microsoft. Microsoft pays a monthly fee for the treatment services operated by the city. Since the QWRU includes pre-existing treatment infrastructure and is set up to accommodate growth, it made most sense to have the City of Quincy operate the facility.

After the initial arrangement, the City of Quincy and Microsoft agreed that other companies’ data centers may connect to the treatment plant, if needed. However, future companies would have to pay connection fees to cover their share of the construction costs, additional investment costs for any necessary upgrades that may be needed to accommodate their flows of industrial wastewater, and their ongoing share of the operational costs. The QWRU took about 10 years to plan, design, construct, and test.

Benefits

Reduces the amount of potable water for data center cooling needs: With a circular water treatment system (138 million gallons per year, 522 million liters per year) the data centers rely significantly less on potable water from local groundwater supplies. Additional efforts by the city to use water from the Columbia River to compensate for the water lost to evaporation, further reduces the reliance on groundwater supplies (260 million gallons per year, 984 million liters per year).

Accommodates future growth and stabilizes rates for municipal wastewater treatment: The QWRU’s closed-loop system prevents discharge of TDS-rich blowdown water from data centers to the MWRF. Because of the reduced volume of water from the cooling center, the MWRF can also more easily accommodate future residential growth and keep customer rates lower.

Protects the environment: With the QWRU in place, the treated industrial wastewater is not discharged into the environment. The brine from the HES and RO facilities is disposed of in accordance with the state law. By extracting less potable groundwater, the City of Quincy also helps preserve its deep aquifer.

Increases drought resilience through water source diversification: As the City of Quincy lies in a notoriously arid region, it is increasingly difficult to justify water conservation measures for other uses, while still using potable groundwater to cool data centers. Meanwhile, having multiple, varied water supply sources (potable groundwater, treated industrial wastewater, Columbia River Basin Project water, municipal reclaimed water) increases resilience to drought. For example, during a hot, dry period in 2021 when water demand was very high, the Quincy-Columbia Basin Irrigation District shut off the pumps bringing water from the irrigation canal as make-up water to the circular system at the data centers. At this point, the QWRU was able to switch to potable groundwater because it still had access to that additional source of water.

Helps attract and retain industries: Because the reuse project lowers the use of groundwater, the city can meet the water supply needs of the growing data center industry for the near future. The reuse project also provides a model for increasing water supplies using reuse to accommodate future growth. Limits on potable groundwater use are now very unlikely to force existing industries to move their operations to other locations. Using less potable water for cooling in data centers also means less water is extracted from the aquifer beneath. Additionally, since the food processing industry is expected to grow, Quincy can now more easily accommodate new food processors that may need to rely on groundwater.

Contributes to Microsoft’s goal of being water-positive by 2030: The project substantially reduces demand on traditional freshwater supplies. This aligns it with Microsoft’s ambitious commitment to be water positive by 2030—that is, to replenish more water than it consumes across all of its operations.

Lessons Learned and Conclusions

Lessons Learned

Plan holistically: The QWRU would have been designed differently if all options for water reuse had been available 20 years ago, including the option of using reclaimed municipal or Columbia River Basin Project water for data center cooling. For example, when using Columbia River Basin Project water, the treatment system would not have to be designed to treat Quincy’s groundwater supplies, which needs substantial softening and filtration prior to use. However, designing the system to treat potable groundwater offered the QWRU the flexibility to use groundwater when drought conditions lowered flows in the irrigation canal. It took a long time to design, construct, test, and commission the many components of the QWRU. There are more efficient ways to design and build a system like this one, but options were limited by existing infrastructure and designated use of available land. Other data centers that are geographically too far away to connect to the QWRU will likely work with the city to pursue different, cost-effective options with equally minimal impact on Quincy’s water resources.

Industry can be part of the solution to provide suitable treatment and fit-for-purpose water: Most municipal wastewater treatment plants, including Quincy’s MWRF are not designed to treat large volumes of industrial wastewater, specifically those with high TDS concentrations. The right regulations and engagement can involve industry in paying for new treatment facilities that can process industrial wastewater separately. In cities where industries generate copious amounts of wastewater, governing and regulatory authorities can create and implement environmental programs for pretreatment and control of industrial pollutants. Regulation and enforcement are essential for curtailing the risks of chemical pollutants and ensuring the successful operation of industrial and municipal wastewater treatment plants and reuse applications.

The case of Quincy and Microsoft also demonstrates that it is key for corporate leadership to recognize the added benefits for them, including water that better meets their needs and improved public perception. Investments in such a project also stem from the economic resilience of the data center industry, which is a robust industry and a stable partner that can commit long term to using and paying for a system like the QWRU.

Institutional learning and coordination are important: Not all water in the U.S. Bureau of Reclamation and Quincy Irrigation District irrigation canal was designated for irrigation—some was designated for municipal and industrial purposes and may not be used for irrigation. Not all city officials were aware of this when the planning for the QWRU started. Over time and in coordination with the Bureau of Reclamation and Quincy Irrigation Districts, agreements were put in place for the City of Quincy to use canal water for data center cooling.

Practice makes perfect: The QWRU system took 10 years to build; the system’s units had to be modified through trial and error during testing to function smoothly. Through extensive testing and iterations, the treatment processes were adjusted to meet the incoming and outgoing water quality requirements. Since water quality requirements vary by location and use, treatment systems need careful gauging.

Bring community on board through public engagement: The City of Quincy encourages its citizens to use water consciously. It has been promoting responsible water use for many years; this—along with the fact that Microsoft and fellow data centers provide jobs and are “good neighbors”—mean that there has generally been broad public approval of the QWRU during construction and ongoing operation.

Conclusions

The QWRU is the outcome of a solutions-oriented public works department, public acceptance, institutional support, and the strong mission of an industry partner to become water positive by 2030. Carrying out 10 years of planning, construction, and testing to launch a functional water reuse system that can accommodate growth is a testament to the strong partnership and will of all involved stakeholders. The design of the QWRU incorporated the city’s preexisting water and wastewater infrastructure, with some components relying on the city’s existing industrial wastewater treatment infrastructure and others built specifically to recycle the blowdown cooling water. Going forward, the QWRU uniquely equips the City of Quincy with a best-in-class water reuse system that demonstrates their commitment to being a responsible steward to its people, industry, and the water resources it depends on.

Background Documents

- City of Quincy. 2014. Water supply and facility agreement [amended]. City of Quincy. 2020. Fact sheet for city waste discharge permit CQ-010: Sabey Data Center Properties, LLC.

- City of Quincy. 2021. 2020—City of Quincy, WA annual report.

- City of Quincy. 2021. Quincy Water Reuse Utility Quincy 1 water plan—Quincy City Council meeting 01 June 2021.

- Microsoft. 2020. Microsoft will replenish more water than it consumes by 2030.

- U.S. Bureau of Reclamation. 2017. City of Quincy 5-year nonagricultural discharge authorization.

- Washington State Department of Ecology. 2006. Reclaimed water permit number ST 5278.

- Washington State Department of Ecology. 2015. Fact sheet for reclaimed water permit ST0005278: City of Quincy Water Reclamation Facility.

- Washington State Department of Ecology. 2018. Fact sheet for NPDES permit WA002106-7: Quincy Industrial Wastewater Treatment Facility.

- Washington State Legislature. 1992. Chapter 90.46 RCW: Reclaimed water use.

- Washington State Legislature. 2018. Chapter 173-219 WAC: Reclaimed water.