Basic Information about the Emission Standards Reference Guide for On-road and Nonroad Vehicles and Engines

Overview of Mobile Sources

Air pollution in the United States comes from many types of engines, industries, and commercial operations. Pollution sources that move are known as "mobile sources." These sources include vehicles, engines, and motorized equipment that produce exhaust and evaporative emissions. Examples of all other (non-mobile) sources of air pollution include power plants, factories, and manufacturing processes.

Mobile sources include a wide variety of vehicles, engines, and equipment. "On-road" or highway sources include vehicles used on roads for transportation of passengers or freight. "Nonroad" (also called "off-road") sources include vehicles, engines, and equipment used for construction, agriculture, recreation, and many other purposes. Within these two broad categories, on-road and nonroad sources are further distinguished by size, weight, use, and/or horsepower.

Mobile Source Sectors Regulated by EPA

| Industry | Description |

|---|---|

| Aircraft | Commercial aircraft engines |

| Heavy-duty vehicles | Heavy trucks and buses: large pick-ups, delivery trucks, recreational vehicles (RVs), and semi trucks |

| Light-duty vehicles | Passenger cars and light trucks: minivans, passenger vans, pickup trucks, and sport-utility vehicles |

| Locomotives | Diesel-powered engines used in freight and passenger rail, line-haul and switch locomotives |

| Motorcycles | On-road 2- and 3-wheeled vehicles, mopeds, and scooters |

| Marine compression-ignition (CI) engines | Auxiliary and propulsion engines used by all types of recreational and commercial vessels: small fishing boats, tugboats, ocean-going ships Marine auxiliary engines: small generator sets to large generator sets on ocean-going vessels |

| Marine spark-ignition (SI) engines and vessels | Gasoline boats and personal watercraft: pleasure boats, jet-skis, outboard engines, and sterndrive/inboard engines |

| Nonroad CI engines and equipment | Construction and agricultural equipment: excavators, paving equipment, tractors, combines, bulldozers, and skidders |

| Nonroad large SI engines and equipment | Gasoline and propane industrial equipment: forklifts, generators, airport service equipment, compressors, and ice-grooming machines |

| Nonroad small SI engines and equipment | Small gasoline lawn and garden equipment: lawnmowers, leaf blowers, chain saws, and string trimmers |

| Recreational engines and vehicles | Land-based recreational vehicles: snowmobiles, dirt bikes, and all-terrain vehicles (ATVs) |

| Fuel Type | Description |

|---|---|

| Low sulfur gasoline | Established in conjunction with the Tier 2 light-duty vehicle standards to maintain the performance of catalytic converters. |

| Ultra-low sulfur diesel (ULSD) fuel | Covers highway, nonroad, locomotive, and marine diesel fuel. ULSD is necessary for new advanced emission control technologies and it contributes to particulate matter reductions in the existing fleet of nonroad engines and equipment. |

EPA’s Approach

EPA regulates the emissions from mobile sources by setting standards for the specific pollutants being emitted. EPA established progressively more stringent emission standards for carbon monoxide, hydrocarbons, nitrogen oxides, and particulate matter, starting in the mid-1970s for on-road vehicles and in the early 1990s for nonroad engines and equipment. Emissions standards set limits on the amount of pollution a vehicle or engine can emit.

EPA realizes that to reduce mobile source pollution we must address not only vehicles, engines, and equipment, but also the fuels they use. So we have set sulfur standards for gasoline, on-road diesel fuel, and nonroad diesel fuel.

The road to clean air also depends on extensive collaboration between EPA and vehicle, engine, and fuel manufacturers; state and local governments; transportation planners; and individual citizens. This integrated approach to mobile source emission control is responsible for greatly reducing mobile source air pollution during the last 30 years. Technological advances in vehicle and engine design, together with cleaner, higher-quality fuels, have reduced emissions so much that EPA expects the progress to continue, even as people drive more miles and use more power equipment every year.

Manufacturers’ and Refiners’ Responsibilities

Once EPA sets emission standards for a particular engine and/or vehicle category, manufacturers must produce engines that meet those standards within the timeframe of the corresponding implementation schedule.

The Clean Air Act (CAA) requires every engine and motor vehicle within the chain of commerce in the United States to meet a set of emission standards and conformity requirements. Anyone wishing to sell an engine or vehicle within the United States must demonstrate compliance with the CAA and all applicable EPA regulations. Upon adequate representation of conformity by the manufacturer and possibly confirmatory testing by EPA, EPA may issue a Certificate of Conformity which provides authorization for production and sales within the United States.

The certification process begins when a manufacturer submits an application for certification to EPA for a group of vehicles or engines having similar design and emission characteristics. EPA requires manufacturers to provide detailed information to show that they have met all of the applicable requirements to qualify for a certificate of conformity. The application for certification describes those vehicles or engines specifically covered by the certificate of conformity. The certificate is a license to produce and sell the vehicle and covers only those vehicles or engines specifically described in the application.

All of EPA’s emission regulations specify test procedures to measure engine or vehicle emission levels. EPA uses the test results to determine compliance with the applicable emission standards.

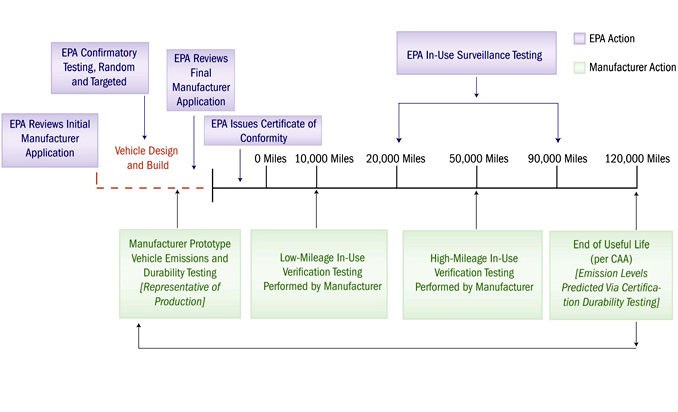

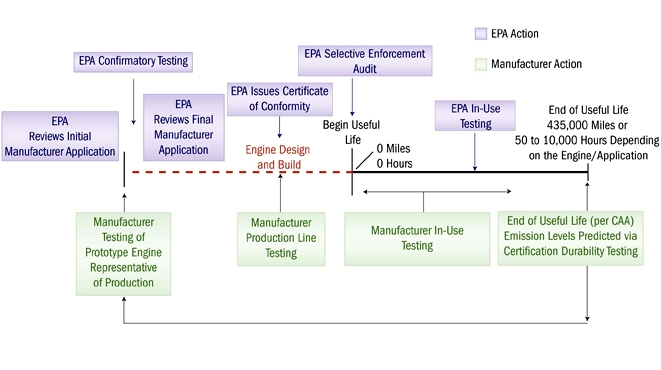

The number and types of tests vary according to the regulated sector. Certification testing is a form of compliance testing that is required as a condition of certification and is generally performed prior to issuing a certificate. In-use testing occurs after the vehicles or engines have been certified, generally on privately used vehicles or engines. Production line (or assembly line) testing audits emission levels of vehicles or engines that are in production, but not yet in service, to confirm that the manufacturer is building compliant vehicles.

Compliance Life of a Light-Duty Vehicle

Compliance Life of a Heavy-Duty Highway and Nonroad Engine

Over time, manufacturers have responded to tighter emission standards by improving engine and vehicle technology, including:

- designing highly efficient combustion systems to minimize exhaust pollution

- introducing vapor recovery systems to capture evaporating gasoline

- using computer technologies to monitor and control engine performance

- developing effective "after treatment" technologies, such as catalytic converters and particulate filters that remove pollutants from the exhaust stream before they can escape into the atmosphere

Parties in the fuel industry, including petroleum refiners and importers, and marketers, distributors, and carriers of gasoline and diesel fuel, must ensure that they meet the standards and testing and reporting requirements that they are subject to.

Standards Set by Other Government Entities

Under the CAA the California Air Resources Board (CARB) may also adopt and enforce its own emissions standards. However, regardless of whether a manufacturer receives CARB approval, all new motor vehicles and engines must still receive certification from EPA before the vehicle is introduced into commerce.

European emission standards define the acceptable limits for exhaust emissions of new vehicles sold in European Union (EU) member states. The emission standards are defined in a series of EU directives staging the progressive introduction of increasingly stringent standards.