CHP's Role in Decarbonization

CHP's key roles in a clean energy market are to:

- Reduce emissions while the grid transitions towards cleaner energy.

- Support solar and wind power resources in microgrids to increase on-site reliability and resiliency.

- Reduce emissions in sectors that are hard to decarbonize.

CHP Can Reduce Emissions While the Grid Transitions Towards Cleaner Energy

CHP requires less fuel to produce a given energy output, and avoids transmission and distribution losses that occur when electricity travels over power lines. By capturing and using heat energy that would otherwise be wasted, CHP systems operate far more efficiently than grid electricity and on-site heating. Typical CHP total system efficiencies are 65 to 80 percent. Depending on the application, this efficiency advantage can result in significant carbon dioxide emissions reductions.

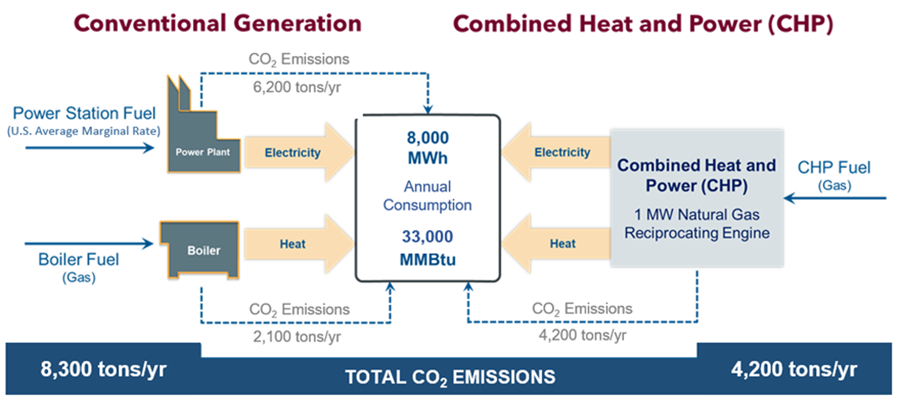

The figure below shows how a conventional 1 MW CHP system would produce about half (4,200 tons) of the annual CO2 emissions that grid-based electricity and a conventional boiler would (8,300 tons), assuming national average marginal grid emissions rates.

Note that this figure is based on conventional grid electricity, which is predominately fossil-based. However, organizations often have a choice in their electricity sources and can choose to purchase renewable electricity. The greenhouse gas (GHG) emissions benefits of CHP will vary depending on the renewable energy choices organizations make. Learn more about renewable energy choices available to organizations.

Unless there is a planned downtime, most CHP systems are operated continuously; in that operating mode, CHP consistently reduces the demand for grid electricity supplied by the local utility. As a result, the operation of marginal grid generators (selected to meet peak demand at any given hour) is consistently reduced. Marginal grid generators vary depending on location, time of day, season, and grid demand. Depending on the type of CHP, its location, and its operational profile (full load or less), CHP can continue to provide benefits until regional grids have transitioned to more renewable energy. As regional grids continue to become cleaner, new and existing CHP using low-carbon fuels will continue to provide emissions benefits.

CO2 Emissions Savings: CHP Compared to Conventional Generation

CHP's Role in Corporate GHG Accounting

Corporations accounting for GHG emissions across their value chain look to guidance and standards provided in the corporate GHG Protocol. Interest in low-carbon options has grown, but the protocol's approach to CHP (pdf) has not changed: it accounts for CHP in the same way (xls), with associated emissions based on the GHG profile of the fuels consumed and the CHP system's efficiency.

CHP emissions are accounted for as Scope 1, or direct, emissions when the CHP facility is located within the facility boundary. At the same time, the CHP will displace amount of grid electricity consumed by the facility. The CHP could also be accounted for in a facility's Scope 2 emissions when the CHP provides energy from outside the facility boundary. However, in this case, when CHP emissions are calculated using average grid emissions factors, they are separately quantified and separately reported in a company's public GHG report as optional information. This is done to avoid the factors resulting in an overcounting or undercounting of emissions.

CHP's Ability to Further Reduce GHG Emissions with Low-Carbon Fuels

Because of CHP's ability to capture and utilize waste heat, it makes better use of limited renewable fuel resources compared to other less efficient technologies.

Several solid and gaseous low-carbon renewable resources that can be used as fuels in a CHP system: agriculture biomass, biofuels, digester gas, landfill gas, solid biomass, wood, and wood products. Each of these is found in select areas. Applications such as the pulp and paper industry, landfills, and wastewater treatment plants have successfully used these resources for many years.

As of December 2020, there are over 750 CHP installations using low-carbon fuels. Low-carbon biogas and biomass fuels will continue to play a role when they are the most economic option for facilities with access to them. As an example, industrial facilities in the lumber and paper industries have been using renewable biomass fuels in boiler/steam turbine CHP systems since the early 1930s.

In a cleaner energy sector, the potential emissions from grid electricity generation will tend to be small due to a greater share of electricity coming from renewable and clean energy resources. This means that CHP systems will need to operate with low-carbon fuels to be as clean as or cleaner than separate heat and power generation.

The McAlpine Creek Wastewater Management Facility in Pineville, North Carolina, is the largest plant operated by Charlotte Water, treating up to 64 million gallons each day. In 2017, the facility installed a 1 MW CHP system to heat its digesters. By replacing an old boiler system and using on-site methane fuels (rather than flaring it), the CHP system reduces GHG emissions and saves Charlotte Water $300,000 in energy costs each year. Furthermore, Charlotte Water sells the excess electricity to Duke Energy under a power purchase agreement, generating more revenue.

For more information, visit https://chptap.ornl.gov/profile/126/McAlpineWWTP-Project_Profile.pdf.

Emerging Low-Carbon CHP Fuel Options

Low-carbon fuel options where long-term supply is available constitute about 5 percent of operating CHP in the United States. There is a growing interest in using new low-carbon fuels for CHP that could be more prevalent than the current options and that could use the existing natural gas infrastructure. Two new low-carbon CHP fuel options of interest are renewable natural gas (RNG) and green hydrogen (hydrogen produced using renewable energy).

RNG is biogas that is captured and treated until it has the same composition as natural gas. Besides easy transportation through the natural gas infrastructure, current natural-gas-based CHP systems have the potential to convert to RNG use and can potentially support hydrogen blends. CHP systems are undergoing research and development to enable 100 percent hydrogen combustion, and some engine models are already hydrogen-capable. Green hydrogen, formed from using renewable power such as solar in the electrolysis process, is another potential fuel for certain CHP technologies.

RNG and green hydrogen are expected to have limited CHP application in the near term. Targeted use of RNG and green hydrogen with CHP in large industrial facilities could be an effective use of these limited resources, since these facilities rely on on-site combustion processes for high-temperature heat that current electric technologies cannot cost-effectively produce. The degree to which these fuels can be used will also vary depending on the specific CHP technology.

CHP Adds Grid Resiliency to Solar and Wind Power Use in Microgrids

Studies suggest that energy storage (both in front of and behind the meter) will be needed to manage the variable nature of wind and solar power. However, most current battery storage alternatives are not capable of long-term storage (maxing out at 4 to 6 hours) or are not cost-effective. The current expected growth rates for cost-competitive storage capacity leave a gap in the market that CHP can fill, particularly in microgrids.

- CHP systems can support variable renewable energy resources, such as solar photovoltaics and wind, because they are able to provide uninterrupted power (excluding planned maintenance activities).

- CHP use can be coordinated with renewable energy use to provide power and heat when renewable energy is not available or during extended grid outages.

- CHP can serve as the backbone for microgrids by providing a reliable baseload source of electricity and thermal energy to support other distributed energy resources such as solar, wind, and energy storage.

- CHP is a proven way to resolve operational disruption that could otherwise lead to material and revenue losses.

- CHP provides load balancing over longer periods than technological solutions that are not cost-competitive at this time and where utility standby rates are onerous.

The Montgomery County Public Safety Headquarters (PSHQ) is a 400,000-square-foot facility that provides critical services to the county's 1 million residents. Following a 2012 derecho that left residents and businesses across the county without power for days, the county government decided to invest in a microgrid to replace existing standby generators. The microgrid is composed of an 865 kW natural gas CHP system and a 2 MW solar array. It provides nearly 90 percent of PSHQ's electric needs and reduces the county's GHG emissions by almost 6,000 tons each year.

For more information, visit https://chptap.ornl.gov/profile/135/MoCoPublicSafetyHQ-Project_Profile.pdf.

CHP Can Reduce Emissions in Sectors That Are Hard to Decarbonize

Because of CHP's efficiency advantage over separately produced heat and power, it can provide the lowest emissions option for sectors that rely on combustion fuels and that are harder to electrify. For example:

- An NREL study (pdf) of economy-wide electrification found that the industrial sector is more challenging than other sectors to electrify because many industrial applications are not well-suited to electrification, especially where there are high-pressure steam and high-temperature direct heat requirements. Industrial applications rely on-site combustion processes as the primary energy sources and electrification technologies do not currently offer a cost-effective solution.

- Industrial sectors with processes requiring high-temperature heat and electricity on-site already rely on CHP; until cost-effective alternatives with lower GHG emissions become available, CHP will remain an economically viable, low-emissions option for facility owners. A recent bottom-up analysis of the industrial sector concluded that there is untapped potential for energy savings by implementing well-known technologies and practices such as CHP, waste heat recovery, efficient motor systems, and energy management practices.

- In the building sector, efficient electric heat pumps are an attractive technology option for reducing emissions in many single-family homes and small commercial buildings. However, CHP that is already in use in large multi-family or commercial buildings and institutional settings with central heating systems will likely continue to be used. CHP systems have continued to be installed in the multi-family and institutional sectors in recent years.

Procter & Gamble installed a 54 MW biomass-fueled CHP system at its Family Care Division plant in Albany, Georgia, in 2017. The system is fueled by crop residuals and wood scraps from local sources and provides process steam to the plant's 70-acre industrial facility, significantly reducing emissions. The plant also helps P&G to meet its renewable energy targets, which apply to both electric and thermal demands. Additionally, the plant sells excess electricity to Georgia Power and the nearby Marine Corps Logistics Base, providing low-carbon electricity to the region.

Image courtesy of Constellation. For more information, visit https://chptap.ornl.gov/profile/428/ProcterGamble-Project_Profile.pdf.