What Is CHP?

CHP is a technology that produces electricity and thermal energy at high efficiencies using a range of technologies and fuels. With on-site power production, losses are minimized and heat that would otherwise be wasted is applied to facility loads in the form of process heating, steam, hot water, or even chilled water. CHP can be located at an individual facility or building or it can be a district energy, microgrid, and/or utility resource that provides power and thermal energy to multiple end-users. CHP equipment can provide resilient power 24/7 in the event of grid outages, and it can be paired with other distributed energy technologies like solar photovoltaics (PV) and energy storage.

During conventional separate power and heat generation, nearly two-thirds of energy is wasted (pdf)—discharged to the atmosphere as heat during generation, transmission, and distribution. By capturing and using heat that would otherwise be wasted and by avoiding distribution losses, CHP can achieve efficiencies of over 80 percent, compared to 50 percent for typical technologies (e.g., conventional electricity generation and an on-site boiler). Because of this increased efficiency, CHP systems can emit less carbon emissions than separate heat and grid power.

Common CHP Configurations

The two most common CHP system configurations are:

- Combustion turbine, or reciprocating engine, with heat recovery unit

- Steam boiler with steam turbine

Combustion Turbine, or Reciprocating Engine, with Heat Recovery Unit

Combustion turbine or reciprocating engine CHP systems burn fuel (natural gas, oil, or biogas) to turn generators to produce electricity and use heat recovery devices to capture the heat from the turbine or engine. This heat is converted into useful thermal energy, usually in the form of steam or hot water.

Steam Boiler with Steam Turbine

With steam turbines, the process begins by producing steam in a boiler. The steam is then used to turn a turbine to run a generator to produce electricity. The steam leaving the turbine can be used to produce useful thermal energy. These systems can use a variety of fuels, such as natural gas, oil, biomass, and coal.

- The Catalog of CHP Technologies includes a comprehensive list of CHP technologies and provides information about their cost and performance characteristics.

- The Biomass CHP Catalog of Technologies presents a detailed technology characterization of biomass CHP systems.

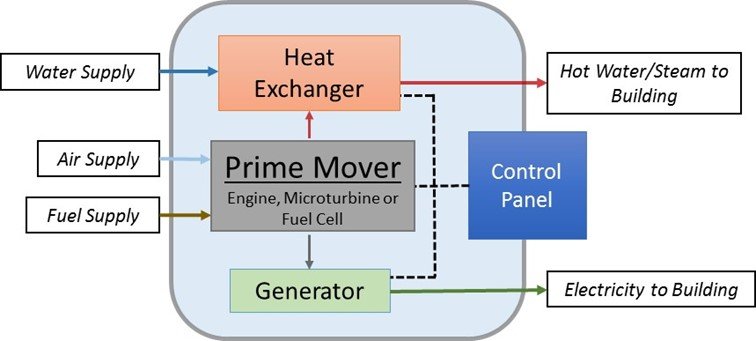

Packaged CHP Systems

Increasingly, “packaged” CHP systems—standardized, factory-built, ready-to-install CHP systems—are also available. These systems can make CHP procurement and installation simpler and quicker.

Packaged systems include a prime mover (i.e., reciprocating engine, microturbine, or fuel cell), a generator, heat recovery equipment, electrical switchgear, emissions control devices, and controls, sometimes packaged in a weather-resistant sound-attenuating enclosure. These systems can be installed as single units or combined to form larger systems. Product offerings for packaged systems have been focused on relatively small (≤ 500 kW) sizes.

- The Catalog of CHP Technologies includes a comprehensive list of CHP technologies, including packaged systems, and provides information about their cost and performance characteristics.

- You can also search for certified systems, compare performance specifications, and learn more about packaged CHP benefits in DOE’s Packaged Combined Heat and Power Catalog (eCatalog).

CHP Applications

CHP is an energy technology that has been used for more than 100 years at a wide variety of facility types, resulting in economic, environmental, and reliability/resiliency benefits. Because CHP produces both electricity and thermal energy, it is best suited for facilities that have year-round coincident power and thermal loads. The types of facilities where CHP is used successfully and where additional potential exists include:

- Commercial buildings—office buildings, hotels, nursing homes, retail

- Residential—multifamily buildings, co-ops, planned communities

- Institutions—colleges and universities, hospitals, prisons, military bases

- Municipal—district energy systems, wastewater treatment facilities, K–12 schools

- Industrial—chemicals, agriculture, ethanol, pulp and paper, food processing

Site-specific factors will determine if CHP might be a good technical and economic fit for your facility. These include operational hours, thermal energy requirements, and utility rates for electricity and gas. Answer a few simple questions to determine if your facility is a good candidate for CHP.