Class II Oil and Gas Related Injection Wells

On this page:

- Use of Class II wells

- Class II well types

- Protecting drinking water resources

- Class II well requirements

- Diesel fuels hydraulic fracturing

- Additional information

Use of Class II wells

Class II wells are used only to inject fluids associated with oil and natural gas production. Class II fluids are primarily brines (salt water) that are brought to the surface while producing oil and gas. It is estimated that over 2 billion gallons of fluids are injected in the United States every day. Most oil and gas injection wells are in Texas, California, Oklahoma, and Kansas.

The number of Class II wells varies from year to year based on fluctuations in oil and gas demand and production. Approximately 180,000 Class II wells are in operation in the United States.

Class II wells fall into one of three categories.

- Disposal wells

- Enhanced recovery wells

- Hydrocarbon storage wells

Class II well types

Disposal wells

During oil and gas extraction, brines are also brought to the surface. Brines are separated from hydrocarbons at the surface and reinjected into the same or similar underground formations for disposal. Wastewater from hydraulic fracturing activities can also be injected into Class II wells.

Class II disposal wells make up about 20 percent of the total number of Class II wells.

Enhanced recovery wells

Fluids consisting of brine, freshwater, steam, polymers, or carbon dioxide are injected into oil-bearing formations to recover residual oil and in limited applications, natural gas.

The injected fluids thin (decrease the viscosity) or displace small amounts of extractable oil and gas. Oil and gas is then available for recovery. In a typical configuration, a single injection well is surrounded by multiple production wells that bring oil and gas to the surface.

The UIC program does not regulate wells that are solely used for production. However, EPA does have authority to regulate hydraulic fracturingThe process of using high pressure to pump sand along with water and other fluids into subsurface rock formations in order to improve flow of oil and gas into a wellbore. when diesel fuels are used in fluids or propping agents. During hydraulic fracturing, another enhanced recovery process, a viscous fluid is injected under high pressure until the desired fracturing is achieved, followed by a proppant such as sand. The pressure is then released and the proppant holds the fractures open to allow fluid to return to the well.

Enhanced recovery wells are the most numerous type of Class II wells. They represent as much as 80 percent of the total number of Class II wells.

Hydrocarbon storage wells

Liquid hydrocarbons are injected into underground formations (such as salt caverns) where they are stored, generally, as part of the U.S. Strategic Petroleum Reserve.

Over 100 liquid hydrocarbon storage wells operate in the United States.

Protecting drinking water resources

Extraction of oil and gas usually produces large amounts of brine. Often saltier than seawater, this brine can contain toxic metals and radioactive substances. Brines can damage the environment and public health if discharged to water or land. Deep underground injection of brines in formations isolated from underground sources of drinking water prevents soil and water contamination.

When states began to implement rules preventing disposal of brine to surface water bodies and soils, injection became the preferred way to dispose of this waste fluid. All oil and gas producing states require the injection of brine into the originating formation or similar formations.

Class II well requirements

States (including federally recognized tribes and U.S. territories) have the option of requesting primacy for Class II wells under either Section 1422 or 1425 of the SDWA.

Under Section 1422 states must meet EPA’s minimum requirements for UIC programs. Programs authorized under section 1422 must include well owner and operator requirements for:

- Construction

- Operation

- Monitoring and testing

- Reporting

- Closure requirements

Under Section 1422 enhanced recovery wells may either be issued permits or be authorized by rule. Disposal wells are issued permits. The owners or operators of the wells must meet all applicable requirements, including strict construction and conversion standards and regular testing and inspection.

Under Section 1425 states must demonstrate that their existing standards are effective in preventing endangerment of USDWs. These programs must include requirements for:

- Permitting

- Inspections

- Monitoring

- Record-keeping

- Reporting

Class II direct implementation permitting, transparency, and efficiency

EPA’s UIC Program is taking steps to improve efficiency and transparency in permitting of Class II permits issued by the EPA (direct implementation). In support of this effort, EPA developed a document to clearly communicate the approach EPA takes when conducting a completeness review of Class II permit applications received by EPA.

Review EPA's completeness review checklist.

Diesel fuels hydraulic fracturing

Oil and gas producers use hydraulic fracturing to stimulate wells and recover oil and natural gas from geologic formations. Source rocks include:

- Coalbeds

- Shales

- Tight sandstones

Source rocks are fractured by fluids injected under high pressure. The fractures allow oil and gas to flow to production wells.

In the Energy Policy Act of 2005, Congress created a broad exemption for hydraulic fracturing under the SDWA. Specifically, hydraulic fracturing – except when using diesel fuel – is excluded from the definition of underground injection and is not subject to regulation under the UIC program (SDWA Section 1421(d)(1)(B)).

In 2014 EPA released information clarifying UIC program requirements for underground injection of diesel fuels in hydraulic fracturing. The Agency also released guidance for EPA permit writers implementing UIC Class II requirements.

The EPA has developed the information and guidance to:

- Explain that owners or operators must obtain a UIC Class II permit before injecting diesel fuels for hydraulic fracturing

- Explain EPA's interpretation of the SDWA term “diesel fuels” for permitting purposes

- Describe existing UIC Class II program requirements for permitting underground injection of diesel fuels in hydraulic fracturing

- Provide guidance for EPA’s permit writers preparing UIC Class II permits for diesel fuels use in hydraulic fracturing

Read EPA's revised guidance for diesel fuels hydraulic fracturing and related documents.

Additional information

Learn More

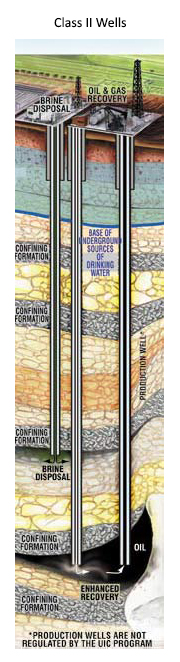

Cross-sectional diagram showing UIC Class II wells