Class III Injection Wells for Solution Mining

On this page:

- Use of Class III wells

- Class III wells types

- Protecting drinking water resources

- General requirements for Class III wells

- Additional information

Use of Class III wells

Class III wells are used to inject fluids to dissolve and extract minerals. Production wells, which bring mining fluids to the surface, are not regulated under the UIC program.

About 165 mining sites with approximately 18,500 Class III wells operate across the nation.

Class III well types

Class III wells are used to mine:

- Uranium

- Salt

- Copper

- Sulfur

More than 50 percent of the salt and 80 percent of the uranium extraction in the United States involve the use of Class III injection wells.

Uranium in-situ leaching (ISL) is the most common method by which uranium is extracted in the United States. A typical uranium mining operation requires injection, extraction, and monitoring wells. The process includes the following steps.

- Injection wells are drilled into the formation containing the uranium.

- A solution known as a lixiviant is injected into the mineral bearing rocks. The solution is allowed to remain in contact with the rocks long enough to dissolve the uranium ore.

- When the lixiviant is almost saturated with uranium, the fluid is brought to the surface via a production well.

- At the surface, uranium is separated from the lixiviant.

- The lixiviant is then injected to extract more uranium.

The majority of Class III wells in the United States are uranium ISL wells.

Salt solution mining wells inject clean water to dissolve the salt. The resulting salt water (brine) is pumped to the surface where the salt is extracted. Two extraction methods are used.

- Under normal flow, water is injected into the well tubing. The saturated fluid is produced through the annulus between the tubing and the casing.

- If the salt is contained in a dome, a single well typically is used. If the salt is contained in multiple, bedded layers, multiple injection wells are used. Salt solution mining wells make up 5 percent of the Class III wells.

Copper is mined using injection wells only in a few states. A sulfuric acid solution is used to dissolve the copper ore.

Sulfur may be mined via the Frasch process. Super-heated steam is injected into the mineral-bearing formation to generate a sulfur solution that can be recovered. Injection wells are not being used to extract sulfur at this time.

Protecting drinking water resources

Solution mining through injection wells is an option that can minimize the environmental footprint and potential impact to surface water compared to more traditional mining processes.

To prevent contamination of ground water (which in many cases is a USDW) by Class III wells, more fluid is extracted than is injected in solution mining processes. This prevents fluids from moving out of the mining areas.

General requirements for Class III wells

All Class III wells are operated under individual or area permits. Contamination from mining wells is prevented by implementing requirements for mining well operators. Before injection begins operators must obtain an aquifer exemption when:

- Solution mining fluids are injected directly into a USDW (which is common in ISL uranium mining)

- Overlying aquifers could subside (a potential occurrence during salt mining)

Additional owner or operator requirements:

- Construct wells with tubing made of materials that are appropriate for the injected fluids, and cased and cemented to prevent the migration of fluids into a USDW.

- Pressure test wells prior to injection.

- During operation, monitor injection pressure and flow rate. Do not inject fluid between the outer-most casing and the well bore.

- Monitor USDWs below and above the mining interval when solution mining fluids are injected into a USDW of 3,000 parts per million total dissolved solids or less.

- Test the casings of salt solution mining well for leaks at least once every five years.

- Properly close (plug and abandon) wells when injection operations are complete.

Additional information

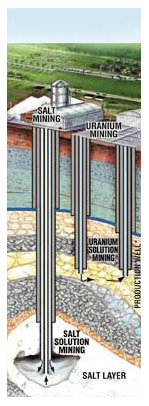

Cross-Sectional Diagram of Class III Wells